crankbait cowboy

Chief Petty Officer

- Joined

- Mar 25, 2013

- Messages

- 620

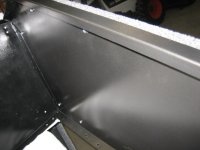

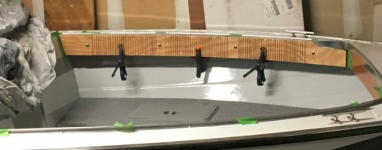

I got my side panels of consoles completed this weekend

cut carpet / applied henry 663 adhesive to flat side / rolled with roller and let sit overnight under weight / stretched over edges and stapled with air stapler / screwed on from metal side with 1/2 inch screws

cut carpet / applied henry 663 adhesive to flat side / rolled with roller and let sit overnight under weight / stretched over edges and stapled with air stapler / screwed on from metal side with 1/2 inch screws