I wanted a project to work on with my grandpa before he's gone and this boat and trailer combo was free from a friends yard. So after many months of research here at iboats.com I decided to go forward on this project! :redface: Any advice or encouragement is very much appreciated as I have no experience with glass work.

I found few small (under 12') boat projects here that detailed how they dealt with a transom rebuild so I thought I would record my effort along the way.

I hauled it to my grandpas where it got power washed and dried over night. Next day I pulled off all of the hardware, then cut out out the seats. I wanted access to the bow and back corners to inspect/ work on damaged hull/transom areas and because they allow water to get trapped under them.

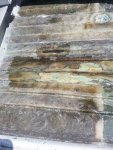

You can also see the damage to the transom. Next free day I have will be cutting/ grinding that out and getting ready for a new install.

Off to place an order for a few gallons of Epoxy!

I found few small (under 12') boat projects here that detailed how they dealt with a transom rebuild so I thought I would record my effort along the way.

I hauled it to my grandpas where it got power washed and dried over night. Next day I pulled off all of the hardware, then cut out out the seats. I wanted access to the bow and back corners to inspect/ work on damaged hull/transom areas and because they allow water to get trapped under them.

You can also see the damage to the transom. Next free day I have will be cutting/ grinding that out and getting ready for a new install.

Off to place an order for a few gallons of Epoxy!