Okay, I'm back to the transom, almost ready but I had some questions. The wood is already a tight fit, I mean I need to beat it with a block and mallet to get it in place (I had to do the same to get the old one out). So the problem is that if I coat it with epoxy, that's only going to make it thicker, should I forego the epoxy on the front and back and just epoxy the edges?

Also, with regards to the holes, I was looking to get some opinions, the last time I did a transom I drilled the holes slightly larger than needed, filled with epoxy and then redrilled to the right diameter needed so that the hole was protected with epoxy. I'm wondering if it really helped or if it would be just as good leaving the hole the size needed for the bolts and just filling it with caulk before inserting the bolts. I did this to the first transom I worked on also but I'm wondering if the caulk was good enough and the epoxy was just overkill. I'm assuming the epoxy would've probably cracked from stress anyway so it may have been useless. I started with a glob of caulk in the hole, pushed the bolt through and slapped some more caulk on both ends of the bolts and washers before tightening it.

Lastly, what torque should I tighten to? I remember from last time, I felt I could keep tightening but I has stopped because I thought it was starting to dig into the wood, is there a certain torque people tend to use, even if it's simply rough like 'one full turn past flush' or something like that.

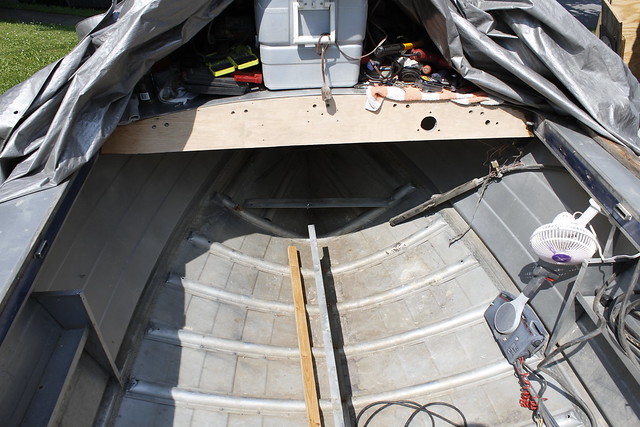

Sorry it isn't a good photo but I was in a rush but here is the old and new transom wood. I realize after looking at this that these boards don't appear to be equal in size at all but oddly enough they are, it's got to be a combo of the angle and the fact that the bottom is 5 inches narrower than the top and I have these bottom to top.