MPrimeaux

Petty Officer 1st Class

- Joined

- May 10, 2019

- Messages

- 240

Well----.5 Ohms is NOT open.-----Open would show infinity !!

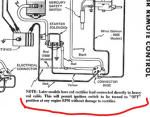

I realize that. Seems like I read somewhere in this venture that an analog meter was needed to set points because a digital VOM wasn't sensitive enough. The manual says advance the mag until the points "break". I can see the needle clearly move at approximately where the spark advance stop was before I moved it. Actually, the needle makes the same movement 4 times per revolution of the flywheel. That is what I expected being a 4 cylinder and having 4.... lobes??? on the shaft of the magneto. I'm an electrician by trade and I realize what an open is, that's the reason for my question. Is the .5 ohms the "break" that I'm looking for or should I get a true open and I've got something wrong. If I have something wrong, does anyone have an idea what that may be? As I said in a previous comment (and I took pictures of my test), I'm having trouble wrapping my head around how I would ever get an open with the magneto housing grounded. I've been looking at the pictures of the magneto before I replaced points and bearings and the only thing I can guess is I've got something touching either the terminal on the points, the main magneto ground terminal, or the points simply aren't opening. I used a dwell plate and pointer to set the 48 degrees, but maybe I didn't tighten the screw or something?