Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,932

I cut the wood for the transom and did a test fit. I then drilled the bolt holes to make sure everything fit well into place. After that I took the wood out and coated it with the 3 coats of spar varnish and made sure to coat the edges and bolt holes very well. When I installed the bolts I coated them with the Loctite marine sealer. I will go with it the way it is and if I ever need to change the board its right there. Just take out 10 bolts and change it. I will have to change it anyway whether I am changing it now or if I have to change it down the line. I greatly appreciate your knowledge and help. By the way, what kind of wood should I have used? Marine grade plywood?

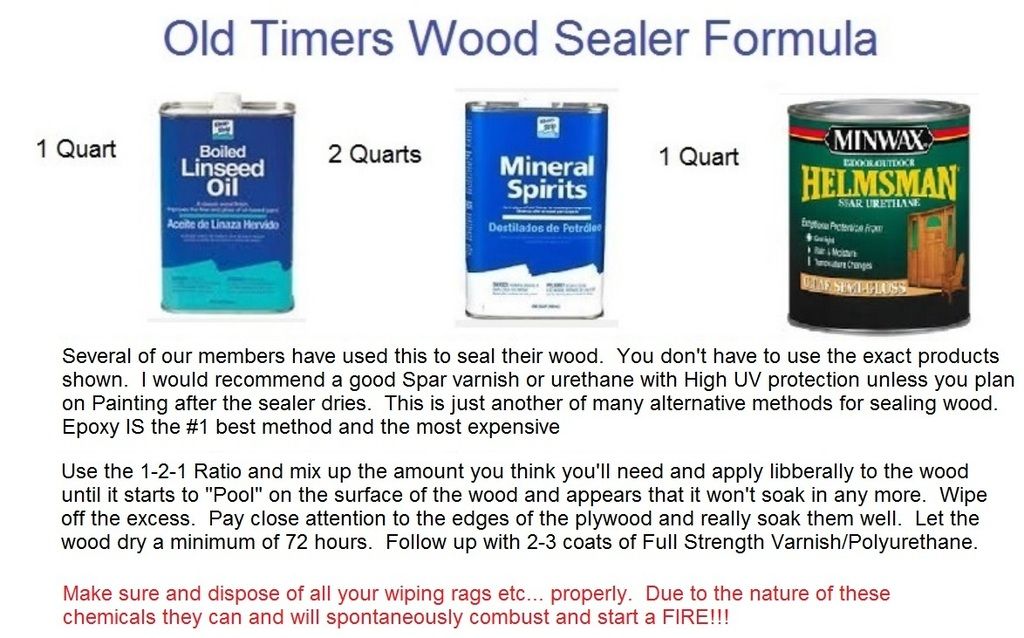

The majority of members and the consensus of most is to use ext. Grade plywood. It's designed for use in a wet environment. The glues used to make it are water proof and the wood used in its laminations are also better suited for a wet environment. The OSB is not. 3M 4200 is a really good sealant to use for bolts and holes. This is another good method to use to seal your wood.