Luke000

Restoration Forum Splash of the Year 2016

- Joined

- Aug 19, 2013

- Messages

- 346

It was finally time to start getting the controls installed, I am using an aluminum steering wheel from my parts bin, it was part of a dash mounted cable and pulley steering system, but the taper on the steering wheel is the same as a modern teleflex-style system, so I opted for a rotary helm with a 20 degree mounting kit and transom mounted clamp. For the throttle, I pieced together a Mercury Quicksilver control with the best parts from 3, I painted the housing with VHT wrinkle black and the handles (and steering wheel) with Sherwin Williams SeaGuard Enamel left over from a LoneStar restoration.

Installation did not go as smooth as I was hoping, the 20 degree mount sat too far back behind the dash and caused the steering wheel to hit the deck and the trim bezel that came with was too big for the dash. So I decided to cut up the 20 degree mount, reduce the angle and offset, then weld it to the 0* mount that came with the rotary helm. I turned a new trim piece for behind the steering wheel since the plastic trim bezel was too big for the spot.

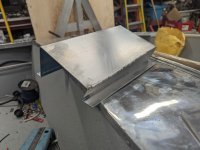

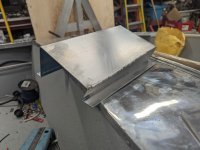

As for the controls, the largest roadblock I hit was my motor is a very early Mercury Mark 55, with the old screw on aviation style electrical connector, but the controls had the newer style cable with a molded push on plug. I spent some time with a meter and traced out each wire on the controls and plug and eventually figured out how to splice the old connector onto the newer style wiring harness, as well as add 2 new battery cables. Soldering the connector was not a fun process whatsoever, but i was able to get it done with lots of flux and the big soldering iron. I also fabricated a proper mount for the controls out of .100" 5052 aluminum. It is 2 pieces that i was able to mock up for a proper angle and then weld together, and rivet onto the hull.

Installation did not go as smooth as I was hoping, the 20 degree mount sat too far back behind the dash and caused the steering wheel to hit the deck and the trim bezel that came with was too big for the dash. So I decided to cut up the 20 degree mount, reduce the angle and offset, then weld it to the 0* mount that came with the rotary helm. I turned a new trim piece for behind the steering wheel since the plastic trim bezel was too big for the spot.

As for the controls, the largest roadblock I hit was my motor is a very early Mercury Mark 55, with the old screw on aviation style electrical connector, but the controls had the newer style cable with a molded push on plug. I spent some time with a meter and traced out each wire on the controls and plug and eventually figured out how to splice the old connector onto the newer style wiring harness, as well as add 2 new battery cables. Soldering the connector was not a fun process whatsoever, but i was able to get it done with lots of flux and the big soldering iron. I also fabricated a proper mount for the controls out of .100" 5052 aluminum. It is 2 pieces that i was able to mock up for a proper angle and then weld together, and rivet onto the hull.