Murray92589

Cadet

- Joined

- Dec 28, 2009

- Messages

- 25

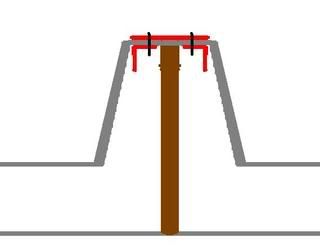

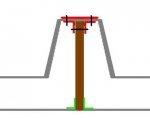

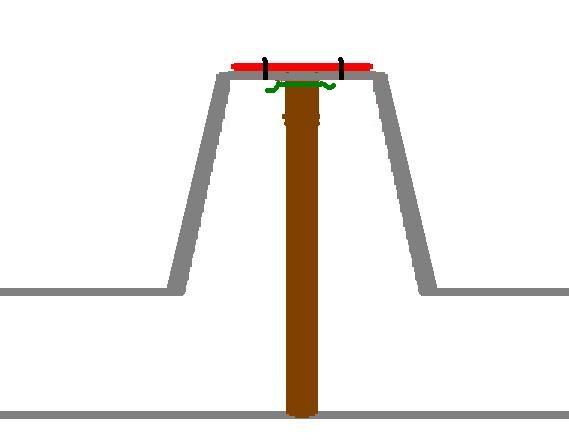

I'm going to start with a couple of pictures. I want to take this boat to the keys and use it in calm water at the end of March, do I need to paint it before then I use it? I'm on a tight budget, could I just sand the rough parts out and use some sort of filler on the big cracks, then use it for a week and paint it later? I'm also concerned about my mast, it has a splice in it (which is supposed to be there) but it seems to be bending a little at the joint, should I worry about that, or will it not hurt the mast?

I'd like for this boat to be in new condition eventually, I'll post new pics of my progress in this thread.

Other threads on this boat:

http://forums.iboats.com/showthread.php?p=2480386#post2480386

http://forums.iboats.com/showthread.php?t=368034

More pics:

http://s646.photobucket.com/albums/uu183/Murray92589/boat/

heres the pictures..

I'd like for this boat to be in new condition eventually, I'll post new pics of my progress in this thread.

Other threads on this boat:

http://forums.iboats.com/showthread.php?p=2480386#post2480386

http://forums.iboats.com/showthread.php?t=368034

More pics:

http://s646.photobucket.com/albums/uu183/Murray92589/boat/

heres the pictures..

.jpg)