So I initially used a slide hammer to get the bearing out and it failed to do so so I ordered the proper tool and finally got it out.

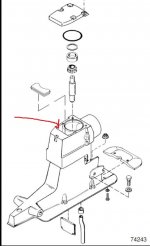

My question now is since the oil seal came out also when I put it back is it pushed all the way against the back of the designated space right? See picture

Also I took out the trim switches one was really dry outside(port) the other had grease all over and also broke up in pieces. When I put the wires back does it have a positive and a negative or it doesn't matter?

My question now is since the oil seal came out also when I put it back is it pushed all the way against the back of the designated space right? See picture

Also I took out the trim switches one was really dry outside(port) the other had grease all over and also broke up in pieces. When I put the wires back does it have a positive and a negative or it doesn't matter?