Original Thor

Seaman

- Joined

- Jun 11, 2020

- Messages

- 61

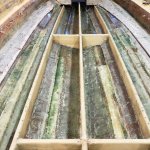

So I tabbed in my transom late last night and got home from work and this is what I found. I seems all good and solid and I used a pile of resin and didn't look like that when i left it. It was already setup and couldn't be worked anymore. Do you think its just the old tabbing that I didn't grind down all the way just transfering the white colors of the old fibers?