- Joined

- Jul 18, 2011

- Messages

- 18,954

I noticed towards the end of the season that the vinyl seating in the cockpit of my Formula 330 SS is starting to dry up and crack. . .

A few places now, but these things only get worse.

So, I am planning on re-doing the seats this winter. I plan on keeping the boat a few more years, and if I just let the seats go as they are, they will probably be a mess in 3 years. Probably best to do it now and get a few years of use and then no have to worry about it when selling.

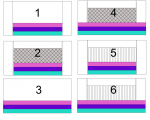

The seats are mostly white, but do have a 3-band color scheme, as you can see below.

I sort of like design #5 so far, with the banded section in the middle of each piece. I was thinking about a diamond quilt for the center section, but that may be too busy. I also searched some substitute colors of Nautolex (actually Boltaflex).

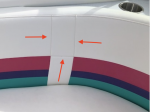

Here is a close-up of the existing colors

Anyway, I've got a bunch of sample swatches on order to see how the colors and texture look in real life.

Then I got to get an industrial sewing machine (see my other thread on the topic). I tried making seat covers for my previous boat using a household machine and it was extremely difficult. I plan on getting a 'walking foot' 'needle/compound' feed machine, which should do quite nicely.

I still have to do some measuring and estimating for material. I'll update as I proceed

A few places now, but these things only get worse.

So, I am planning on re-doing the seats this winter. I plan on keeping the boat a few more years, and if I just let the seats go as they are, they will probably be a mess in 3 years. Probably best to do it now and get a few years of use and then no have to worry about it when selling.

The seats are mostly white, but do have a 3-band color scheme, as you can see below.

I sort of like design #5 so far, with the banded section in the middle of each piece. I was thinking about a diamond quilt for the center section, but that may be too busy. I also searched some substitute colors of Nautolex (actually Boltaflex).

Here is a close-up of the existing colors

Anyway, I've got a bunch of sample swatches on order to see how the colors and texture look in real life.

Then I got to get an industrial sewing machine (see my other thread on the topic). I tried making seat covers for my previous boat using a household machine and it was extremely difficult. I plan on getting a 'walking foot' 'needle/compound' feed machine, which should do quite nicely.

I still have to do some measuring and estimating for material. I'll update as I proceed

Attachments

Last edited: