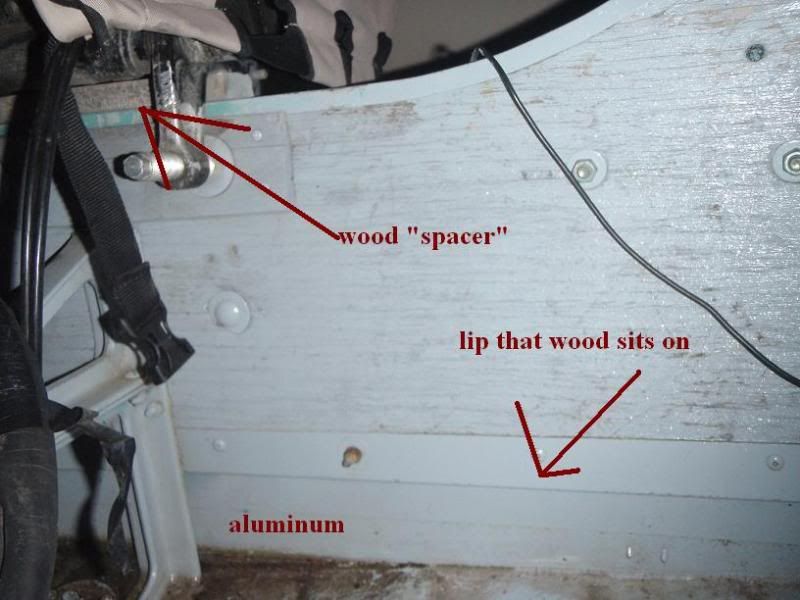

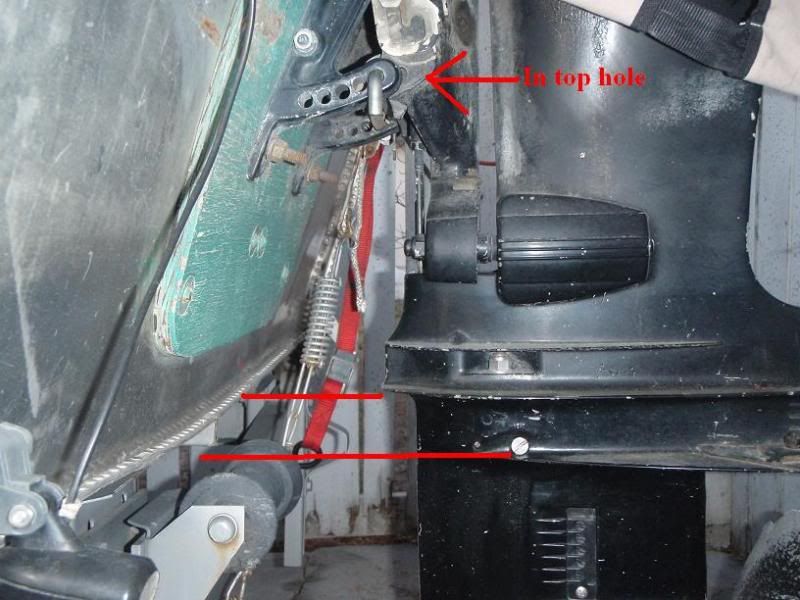

I am going to replace the wood section of my transom on my older areoliner boat, the back side (water side) of the transom is all aluminum and it appears that there is just a 1 inch thick piece of plywood as support on the inside. the plywood does not go right to the floor it is about 6 inches off and it sit on a "lip" but it is the full width. this plywood is bolted to the transom in a few places. the motor appears to be sitting too low and the previous owner looks to have tried to remedy this by adding a spacer which is getting weathered. the way i see it since i am replacing the plywood i can make it taller to get the motor up higher where it should be.

i have 2 questions

what height should i put the motor at? i know the cavitation plate should be right around the bottom of the boat but what pin should i put the motor at to measure where the plate is now and determine how much taller the transom should be. i took 2 pictures to show the different angles.

since the plywood really isn't sitting in any water at all what should i use to seal it up?

here are some pictures. i hope that makes sense

i have 2 questions

what height should i put the motor at? i know the cavitation plate should be right around the bottom of the boat but what pin should i put the motor at to measure where the plate is now and determine how much taller the transom should be. i took 2 pictures to show the different angles.

since the plywood really isn't sitting in any water at all what should i use to seal it up?

here are some pictures. i hope that makes sense