The Poly vs Epoxy is a very controversial argument. Always was, still is and will continue to be until a new technology eclipses both.

Long story short, Epoxy is superior, no one can argue that. The real question is, will you benefit from the superior characteristics of the Epoxy resin?! In an application like yours, the answer is most likely NO. Let me give you an example... what would be the ROI of rebuilding gradma's grocery getter with a 383 stroker with turbo charger?! Most likely nothing. Other than complaining about the darn car burning way more gas than it used to, she may not even notice what she got.

On the same token, epoxy has its applications that justify the extra $$. This fishing vessel is hardly one of them. If you don't care and $$ is not an issue, by all means.. go for it. If you are like the rest of us and do some cost benefit analysis on your financial decisions, save the $$ for a new chirp transducer and multi-function screen.

The tight bond and PL is to glue the different sheets of ply together to form the total thickness of the transom. For example, to glue 2 sheets of 3/4 ply and 1 sheet of 1/2 to form a total transom thickness of 2 inch. TiteBond III is better than PL for this specific purpose - in my opinion - simply because it water resistance but both will work. If the guys in the other forum don't use glue to glue wood together, I am not sure what they would use then.

To glue the new transom (wood shaped, cut to size & up to thickness) to the inner skin of the boat hull, people here use a mix of thickened resin to the consistency of peanut butter (that is why it is generally know and refereed to here on this forum as peanut butter.

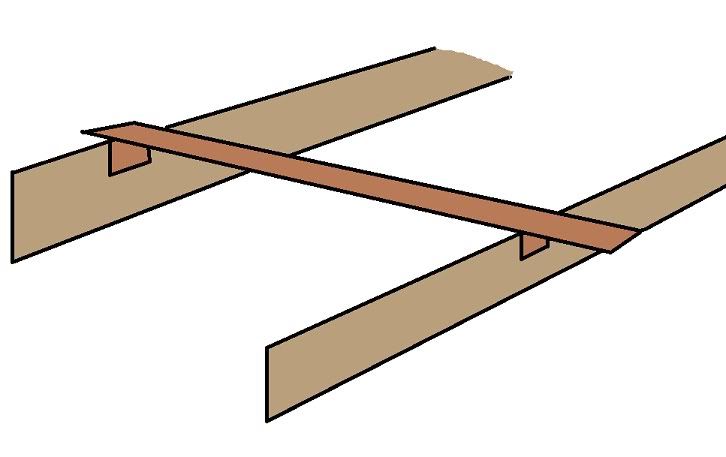

I personally don't like to use this PB for this "gluing" application but I am going out on a limp here and I am sure people will disagree soon. I use PB to create fillets (rounding the corners of 90 degrees where wood intersects) for surfaces that will be glassed over since fiberglass doesn't like sharp corners. Even this application can be accomplished with special type of foam sheets or even plywood/hard wood trims cut at 45 angles or whatever angles needed to make the transition.

The problem with this mix is it is so brittle. Even if you through cut glass into it, it is still not the right ratio of mixing resin and glass. On the contrary, it is much much less. This thickened resin was originally introduced with Epoxy which by itself has an excellent gluing characteristics. Poly on the other hand doesn't have this feature. If there is one good application for epoxy in your rebuild project it would be to glue the transom wood to the inner skin of the hull. You still can use poly elsewhere even on the other side of the transom wood (the one you will see after you install it).

Again, this is just what I would do, you don't have to do that. The popular opinion here is that the PB mix has been used successfully for so many projects even though I don't really know how can we define successfully in this specific context if we never examined the bond between the two surfaces after being in use for a while or compared it to other bonding methods or any other scientific or even systematic approach to evaluate the bond.