No Title

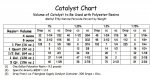

I finally got the transom glued up Sunday morning. I was so nervous. My son was supposed to come over and help but that just didn't work out. I got my wife to hand me the 2X4 clamps. I mixed up one container of 1.5l with a 1% hardener about 250ml of 1/4 chop strand and maybe 750ml of cabisol. That seemed to produce a pretty good mixture. I poured another 1.5l and added the chop strand. I got everything set up and spread the back of the transom piece then mixed hardener and cabisol in the next container and spread that on the transom. Got them put together and clamped. It gave me about 45 minutes which was plenty of time. I took the rest of the pb and started evening out the edges of the transom and the bottom. It set up like a rock. I was super happy with the outcome. I came back Monday morning and finished off with PB to even out the bottom of the transom and the top and side edges. While that was setting up I went across the street and got my in-laws evaporative cooler going. It was about 85? by then. I went back to the boat and sanded down any rough spots then cleaned with acetone then cut some 8" strips of 1708 and started tabbing the bottom. I mixed the resin too heavy and it set up too quick. I don't feel like I was able to wet those bottom tabs as well as I would like. I definitely got better at it once I reduced the hardener to give me some working time. It was harder then I thought. It takes a lot of working to get it all wet in. I used a roller, a brush with the bristles cut short and a metal bubble roller. I'm going to do one more layer of 1708 and then move on to the stingers and the engine mounts. It is like a tank. I am really not even sure I need to do another layer, but that was my plan and I'm sticking to it. So that will be one layer of CSM on front and back of transom wood, then 2 layers of 1708 to tab it all in.