I think I've got the Hull situation in swing,

I have some updates guys, anybody know how to upload photos from mobile using shots from my photo bucket??

I am almost certain that I am going to paint the Hull now. A 2 tone job similar to how it looks now.

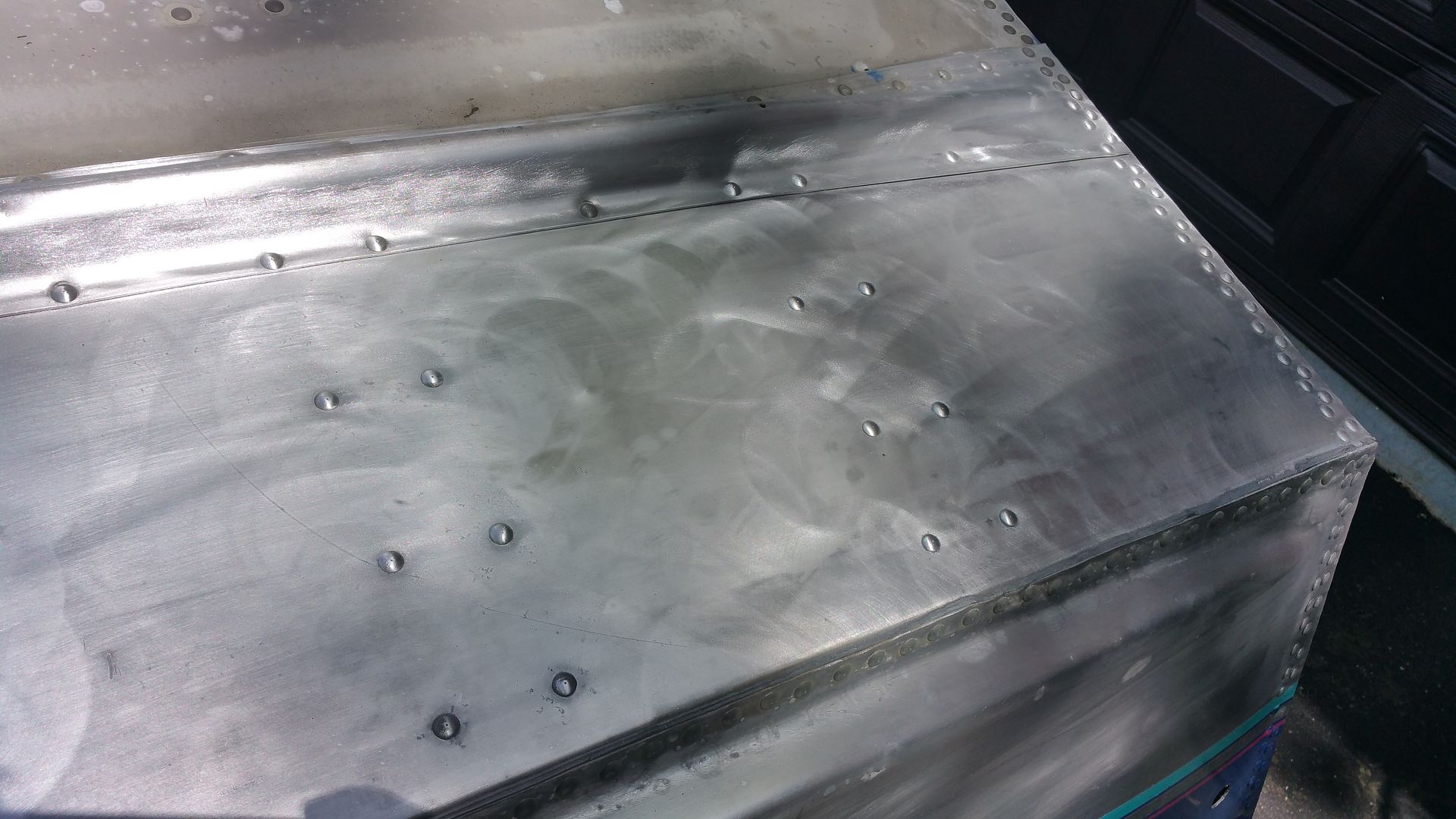

Question in regards to that, I have removed the oxidation layer with 3" nyalox cup brushes, and after that, rinsed it with water.

Let that sit a couple of days and than just today before work mixed up a 1 part to 1 part mixture of a product called ZING (hydrochloric acid chemical) and followed the directions on the bottle.

I plan to do it one more time to finish off the bottle I got this morning when I come home from work.

Is this all that needs to be done in regards to the oxidation? The surface brush revealed what I found in the original leak test and also a few more spots.

These we're all marked with marker. There we're 3-4 small sized holes, I'm thinking JB WELD for those?the seams were leaking good if you turn back to the vid. I also do not see any signs of major pitting, just those small holes ive marked. Also, question about GLUVIT PRODUCT.

I heard it was good and I plan to use it, should I seal the outside and inside? Or just inside? Do you paint it on with a paint brush or use a roller? Could you use a commercial sprayer to apply it? (My dad has one as is professional painter, but was unsure If that product would be sprayer friendly)

Anything else to use?

Thanks