Dignified09@gmail.com

Petty Officer 3rd Class

- Joined

- Apr 9, 2016

- Messages

- 92

Hello and welcome to my thread. I am excited to show you all this project as it is my first attempt at ever rebuilding/restoring anything ever.

A little bit about myself, I am 25 years old, from Minnesota (10,000 lakes ) and have very fond memories of my father taking me out to fish as well as traveling northern MN to Aitkin for the fishing experience as well. This is my FIRST boat ever as well, and I am hoping to gain some helpful knowledge as well as tips or pointers on how to accomplish what I want.

) and have very fond memories of my father taking me out to fish as well as traveling northern MN to Aitkin for the fishing experience as well. This is my FIRST boat ever as well, and I am hoping to gain some helpful knowledge as well as tips or pointers on how to accomplish what I want.

Thank you for taking the time to visit and I hope that I will get some responses from the community.

I have been thouroughly reading through various posts in the past couple of weeks and have gathered a lot of things myself as to what I may need to do or direction I need to take but I am going to need some help from you veterans out there, so I greatly appreciate any comments or help.

Thank you so much, help me get out fishing

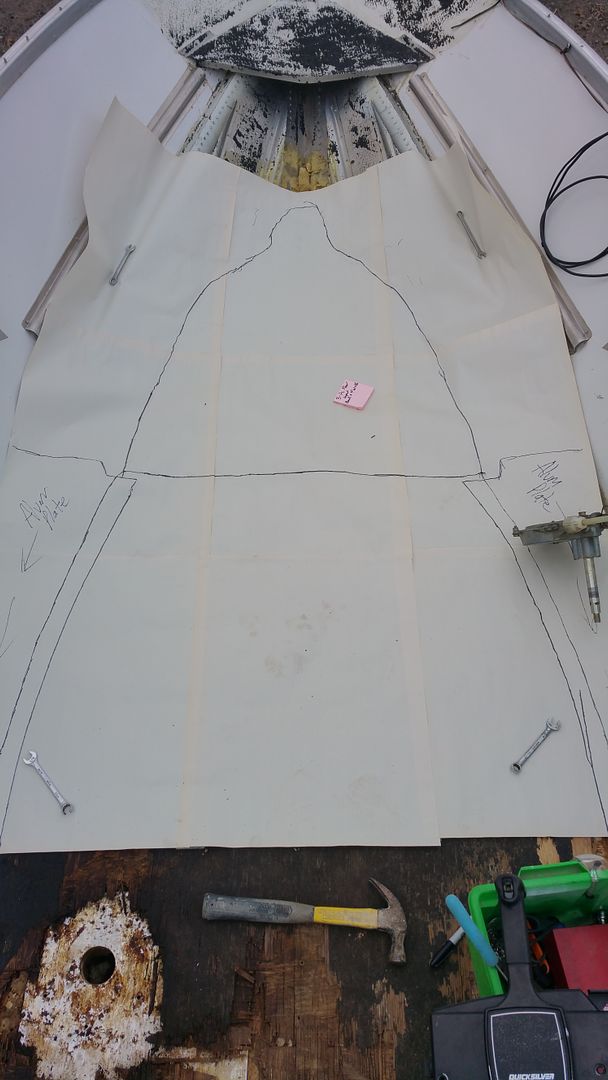

Here is what I have done to the boat already, I have many pictures to help guide anyone who wants to give advice. I will need it. This is a very exciting project for me that I am determined to finish.

so without further ado, here is the 1991 Mirrocraft Troller XL:

[/SIZE][/FONT][/COLOR]

[/SIZE][/FONT][/COLOR]

A little bit about myself, I am 25 years old, from Minnesota (10,000 lakes

Thank you for taking the time to visit and I hope that I will get some responses from the community.

I have been thouroughly reading through various posts in the past couple of weeks and have gathered a lot of things myself as to what I may need to do or direction I need to take but I am going to need some help from you veterans out there, so I greatly appreciate any comments or help.

Thank you so much, help me get out fishing

Here is what I have done to the boat already, I have many pictures to help guide anyone who wants to give advice. I will need it. This is a very exciting project for me that I am determined to finish.

so without further ado, here is the 1991 Mirrocraft Troller XL:

Last edited by a moderator: