from description ? .the shaft is locating fine to the oil pump but not the crankshaft .

as has been posted you may need to rotate the flywheel to aid alignment .

what's interesting is that the old shaft goes home but the new one does not .and that you can get the new one in but it seizes.

have you tried out of curiosity removing the water pump just to be sure nothing is hanging up there.(its probably not but just to cover bases)

also try some engine oil on the shaft to lube the splines , work the shaft in and out to see if it goes further each time you push it up .(disclaimer , I know how that reads but the best i can describe my suggestion) .

Thanks stresspoint. I'm unsure why I'd need to rotate the flywheel, if I can rotate the driveshaft? Maybe I'm missing something here, but shouldn't rotating the driveshaft to align splines do that same thing? Especially on a Yamaha, where there is some wiggle room to line up shift shaft and water pump. (not that I'm even getting that far) I haven't tried removing the waterpump, because I'm nearly certain it's not quite getting that far yet.

To clarify, the old driveshaft does in fact go home and line up with no problem. The whole reason for this repair and switch out from the old lower unit, is that the old lower unit has a problem in the gearcase. I'll have to drill out the gearcase to take a look, but no matter what gear I put the old lower unit driveshaft in (F, R or N), it will not translate power from the prop shaft to the drive shaft.

I have used marine grease to try and work the shaft, many, many times (ha ha), but no luck.

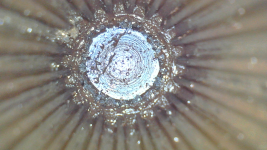

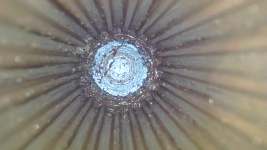

My next step is to try and get a scope camera to look what I'm dealing with for the flywheel splines. If that doesn't help, I may just have to bite the bullet and swap driveshafts.