Taxus812

Petty Officer 2nd Class

- Joined

- Aug 5, 2013

- Messages

- 177

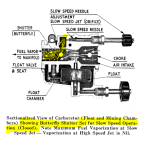

I fully synced the linkage and carb, following the service manual. Everything seemed clean until I reached the last step to adjust the wide-open throttle stop.

That step has you advance the throttle to the wide open position and check the throttle shaft pins on the carburetors are both verticle. My assumption is they will both be exactly verticle (or adjusted utill they are precisely verticle).

This is where my issue is. My upper is about 2 deg more open than the lower in the WOT position. Both throttles are evenly snapped shut in the idol position and move simultaneously, and the cam follower has a small gap. Is this adjustable? My only thought is that there is wear in the link pin retainers or the link pin itself is bent slightly.

The picture does look even, but it isn't. The bottom is slightly off from the top.

Any help is always appreciated.

1991 Johnson 48hp

That step has you advance the throttle to the wide open position and check the throttle shaft pins on the carburetors are both verticle. My assumption is they will both be exactly verticle (or adjusted utill they are precisely verticle).

This is where my issue is. My upper is about 2 deg more open than the lower in the WOT position. Both throttles are evenly snapped shut in the idol position and move simultaneously, and the cam follower has a small gap. Is this adjustable? My only thought is that there is wear in the link pin retainers or the link pin itself is bent slightly.

The picture does look even, but it isn't. The bottom is slightly off from the top.

Any help is always appreciated.

1991 Johnson 48hp

Attachments

Last edited:

![IMG_7163[1].JPG](/data/attachments/389/389289-320332a817f416776ffcc7ce12db4192.jpg)