- Joined

- Jul 18, 2011

- Messages

- 17,710

Greetings,

I've been trying to figure out a cooling/overheat issue with my 1969 Merc 7.5 HP. When I was prepping the engine at the beginning of the season, it was not peeing properly despite a brand new water pump. I set it aside and grabbed the next in line for the dinghy (Yammy 3 HP)

Today I figured it out ( I think) and wanted to share for those who may have same/similar Mercury OB.

Anyway, today I spent some time going through the cooling flow of the Merc. I pulled the lower unit and ran the pump via the drive shaft with a drill . . . good flow. So, on to the next thing. I figured that the insides had some salt build-up, so I ran some Barnacle Buster through the cooling system. It improved things, but still not great. At least the engine was peeing again, but it was not a consistent flow.

So, on to the next thing. I figured that the insides had some salt build-up, so I ran some Barnacle Buster through the cooling system. It improved things, but still not great. At least the engine was peeing again, but it was not a consistent flow.

It seemed like the water jackets around the cylinders were not getting enough water flow. I then noticed a plug on top of the engine block where the upper water jacket was located. I removed the plug and ran the engine, hoping to see water pumping out of the plug hole. What I got was exhaust instead of water .

.

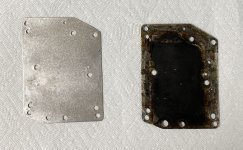

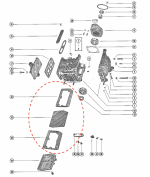

OK, at least I found the issue . . . the gaskets and baffle along the exhaust side of the engine had perforated and exhaust pressure was getting in the cooling system, preventing the water from flowing properly and surrounding the cylinders. See the culprit parts below . . .

.

.

So, I'll be seeing about getting a new set of gaskets and baffle for the engine. It will be nice to have the engine working again.

.

Here are the culprit parts . . .

I've been trying to figure out a cooling/overheat issue with my 1969 Merc 7.5 HP. When I was prepping the engine at the beginning of the season, it was not peeing properly despite a brand new water pump. I set it aside and grabbed the next in line for the dinghy (Yammy 3 HP)

Today I figured it out ( I think) and wanted to share for those who may have same/similar Mercury OB.

Anyway, today I spent some time going through the cooling flow of the Merc. I pulled the lower unit and ran the pump via the drive shaft with a drill . . . good flow.

It seemed like the water jackets around the cylinders were not getting enough water flow. I then noticed a plug on top of the engine block where the upper water jacket was located. I removed the plug and ran the engine, hoping to see water pumping out of the plug hole. What I got was exhaust instead of water

OK, at least I found the issue . . . the gaskets and baffle along the exhaust side of the engine had perforated and exhaust pressure was getting in the cooling system, preventing the water from flowing properly and surrounding the cylinders. See the culprit parts below . . .

.

.

So, I'll be seeing about getting a new set of gaskets and baffle for the engine. It will be nice to have the engine working again.

.

Here are the culprit parts . . .