1985 150hp evinrude E150STLC0S

Trim motor model number 10810N

The book calls for 394176 Trim motor

Trim motor was only working intermittently. Both trim telays tested within range. Fully charged battery, clean connections etc. I bypassed the relays and replicated the same issue.

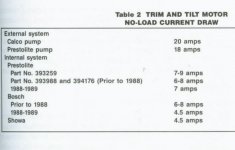

I removed the Trim motor and tested the resistance up and down. Each movement tested at 3.1 to 3.5 or so. My book listed 3 brands and what they should test under a no load test. Not knowing my current brand i wasn't sure. Assuming it was the lowest of the 3 listed it still tested below value

Now to the question. Is my test result too far off to the point where cleaning it won't help. I've read/seen where taking it apart, cleaning, etc led to the motor coming back to specifications.

Trim motor model number 10810N

The book calls for 394176 Trim motor

Trim motor was only working intermittently. Both trim telays tested within range. Fully charged battery, clean connections etc. I bypassed the relays and replicated the same issue.

I removed the Trim motor and tested the resistance up and down. Each movement tested at 3.1 to 3.5 or so. My book listed 3 brands and what they should test under a no load test. Not knowing my current brand i wasn't sure. Assuming it was the lowest of the 3 listed it still tested below value

Now to the question. Is my test result too far off to the point where cleaning it won't help. I've read/seen where taking it apart, cleaning, etc led to the motor coming back to specifications.