Tim Frank

Vice Admiral

- Joined

- Jul 29, 2008

- Messages

- 5,351

I posted in a more "General Question" section of this board. I hope this does not qualify as the dreaded "double-post", but I have since seen similar questions and it is gently pointed out that all of this is covered by info in the "Restoration" section. So I started looking here.

I have searched through many posts and obtained a tremendous amount of pertinent info, and learned a lot. Many thanks.

I now have one last, and fairly specific, question.

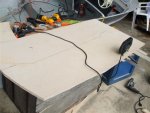

I intend to make up the new wooden transom insert from a double layer of 3/4" marine ply. I will use Resorcinol glue and 1-1/4" S/S screws to laminate the two layers.

Is there any other coating anyone might suggest instead of epoxy?Especially on the edges.

There should be no U/V concerns since it will be completely covered by aluminum.

Any pros or cons that I might be missing?

Thanks,

Tim Frank

I have searched through many posts and obtained a tremendous amount of pertinent info, and learned a lot. Many thanks.

I now have one last, and fairly specific, question.

I intend to make up the new wooden transom insert from a double layer of 3/4" marine ply. I will use Resorcinol glue and 1-1/4" S/S screws to laminate the two layers.

Is there any other coating anyone might suggest instead of epoxy?Especially on the edges.

There should be no U/V concerns since it will be completely covered by aluminum.

Any pros or cons that I might be missing?

Thanks,

Tim Frank

I have a 15 ft Orlando Clipper runabout, vintage c.1959/60.

Remarkable hull shape, quite rounded, and when planing has virtually no wake.

Currently powered by Nissan 40 HP after 30 years with a Johnson 55. Performance is about the same. Full speed ~ 40 MPH.

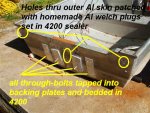

The transom is failing, it appears the layer between inner and outer aluminum skins is shot.

I am pretty good with tools and am prepared to have a shot at this repair.

Has anyone had any experience with this type of repair on Orlando Clippers?

My approace would be to take off the inner skin and remove the remnants of whatever was there....appears to be some sort of wood core, 1 - 1/2 " thick. I would laminate a new core from 3/4" marine plywood, coat it with epoxy resin, and refit.

I plan on adding a pair of diagonal braces from the upper motor securing bolts to the gunwales.

Seems reasonably straightforward.

Any comments, advice, or sources of information on these boats and their Manufacturer would be appreciated.

ID plate on the front says only "Orlando Clipper" , Orlando Boat Company a division of Southern Lighting Corp. and max HP of 50 HP.

Rgds,

Tim Frank