sparkey504

Cadet

- Joined

- May 12, 2021

- Messages

- 11

long story long i have a 2 stroke tohatsu m25c3 that ive had for at least 6 years... it sat up for several years due to broken bolt on impeller housing.... fixed it and rebuilt lower unit essentially last spring.(IM NOT TO FAMILIAR WITH OUTBOARDS or anything to deep into regular engines but i do work on extremely complicated and precise CNC machines for a living so im not completely useless)

I took it out and it ran great for 20 min, died and after several hours ended up getting a tow back.

after probably 2 months of weekends tinkering with it here and there i stopped.

i was recently layed off so im determined to get her fixed while i have the time.

i have it running pretty decent on ears and barrel but idle starts out high and gets lower the longer it ran...As much as i hate to admit it because water was coming out of the pisser i thought warter system was good... turns put thermostat was stuck closed and was likely the cause of my issue last year

NOW TO THE POINT....

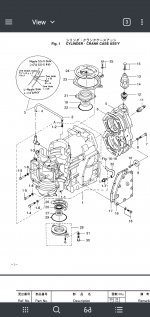

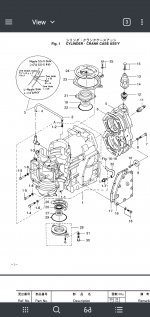

Because of that i want to make sure she is in good health before i take it out...so i did a compression test with both plugs out throttle wide open... Spec is 110psi

top cylinder is 95psi

bottom cylinder is 185psi

I pulled exhaust cover off to see if there was a blockage of some type and while i didnt see any blockages is did find the tip off a fin of the water impeller and it does look like new rubber (water still pisses but going to change reguardless)

so why is the lower cyliner compression 163% than manf spec?

im about to order head gasket so i can pull that off and take a look see... anything else i need to order or look at?

I took it out and it ran great for 20 min, died and after several hours ended up getting a tow back.

after probably 2 months of weekends tinkering with it here and there i stopped.

i was recently layed off so im determined to get her fixed while i have the time.

i have it running pretty decent on ears and barrel but idle starts out high and gets lower the longer it ran...As much as i hate to admit it because water was coming out of the pisser i thought warter system was good... turns put thermostat was stuck closed and was likely the cause of my issue last year

NOW TO THE POINT....

Because of that i want to make sure she is in good health before i take it out...so i did a compression test with both plugs out throttle wide open... Spec is 110psi

top cylinder is 95psi

bottom cylinder is 185psi

I pulled exhaust cover off to see if there was a blockage of some type and while i didnt see any blockages is did find the tip off a fin of the water impeller and it does look like new rubber (water still pisses but going to change reguardless)

so why is the lower cyliner compression 163% than manf spec?

im about to order head gasket so i can pull that off and take a look see... anything else i need to order or look at?

Last edited by a moderator: