LaqueRatt

Chief Petty Officer

- Joined

- Jun 27, 2022

- Messages

- 483

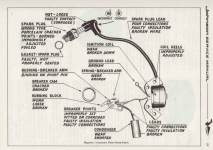

I set the points on my old OMCs using a feeler gauge. Been using one for years, pretty sure am doing it right. Motors always seem to run well, but I've been reading that for best idle and easy starting the points should be timed so that they fire exactly 180 degs apart. I see some are using a multimeter which think I understand, but some are using a fixture. A thin bar with a hole for the flywheel and a pointer. Do I need to buy a fixture to dial these in better or can I just use a multimeter? Can I make a fixture? They look pretty simple.

Motor I'm currently working on is a 76 6 HP Johnny.

Motor I'm currently working on is a 76 6 HP Johnny.