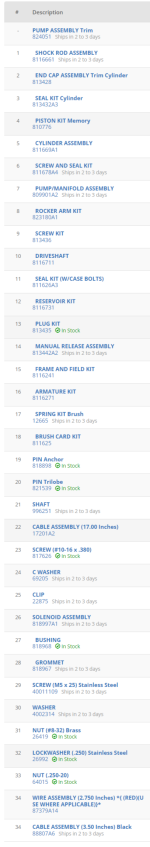

I have a 1996 Force 90hp that I was having a few issues with the tilt & trim. I decided the to take the tilt & trim motor and pump/manifold apart, I got everything back together except for the pump/manifold. I was wondering if anyone would have the diagram of putting the tilt & trim pump/manifold back together. I have design one with the model number 0E182480 any help would be much appreciated.

Thanks Mav

Thanks Mav