I just bought a used pontoon with a Johnson 90 on it. Motor runs well, but the boat does not go as fast as it should. I believe it is a cable adjustment problem because when I force it down a little farther, it picks right up and runs like it should. Same thing in reverse.

Pic2 shows the 2 cables going into the left side of the motor. There is a round adjusting knob on each. I can't find much info on this motor online. Can anyone tell me which cable is the throttle cable; upper or lower? Might my problem be fixed by turning the adjusting knob in the appropriate direction? which direction? Do I have to loosen something up first?

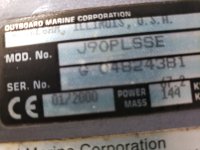

Pic1 shows the model plate on the motor. Note the in the lower left it implies the motor is from 2000, but the "SE" at the end of the model number implies it is from 2009. Any Johnson Gods out there that can settle this piece of trivia?

Thank you for your thoughts.

I am thankful for this wide array of experts here who are willing to share their knowledge.

Pic2 shows the 2 cables going into the left side of the motor. There is a round adjusting knob on each. I can't find much info on this motor online. Can anyone tell me which cable is the throttle cable; upper or lower? Might my problem be fixed by turning the adjusting knob in the appropriate direction? which direction? Do I have to loosen something up first?

Pic1 shows the model plate on the motor. Note the in the lower left it implies the motor is from 2000, but the "SE" at the end of the model number implies it is from 2009. Any Johnson Gods out there that can settle this piece of trivia?

Thank you for your thoughts.

I am thankful for this wide array of experts here who are willing to share their knowledge.