tatoo844

Recruit

- Joined

- Mar 29, 2021

- Messages

- 4

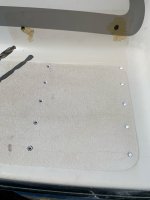

Hello all I need some advice/guidance from this great group. I have a 93 18.5 foot crown line that I love. It to me is perfect. Fishing and playing on the water, mostly fishing. I currently have a trolling plate on the I/O 4.3 motor. It does its job to slow me down. However I am adding a kicker onto the swim deck. 1 to save on gas consumption and 2 as a backup engine to get me off the water in an emergency. I have a panther marine swim deck mount that I just got. My question is I cannot access below my swim deck where I want to put the bracket. I have a few ideas however. 1 is drill from my engine bay into the swim deck pontoon so i can access bolts. 2 which I am going to try is install some nut trivets down from the top into the blind holes and coat them with epoxy to add strength. The kicker is a small 15 hp johnson. The bracket also comes with a support tube to attach to the transom as well. I plan on securing the kicker to the grab rail with a ratcheting strap for additional support. As you can see from the first picture, someone had a electric motor or kicker on there before. Any and all advice is welcomed.