Re: Sunken Cape Craft, Bringing back to life...

Uncle Willie,

Thank you, Sir! You are absolutely correct and I am in the process of re-doing the wiring as depicted in Don S' diagram.

Here are a couple of pictures to prove it...

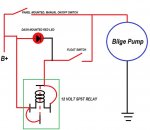

The first one is the flow from the bilge pump through the float switch as done

incorrectly...

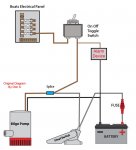

This next one is the flow from the bilge pump using the manual

ON switch...

For what has been happening on this resurrection, here is a quick run down...

1-My neighbor started out his marine career working on outboards, mostly Mercs, so when he heard that I was in the process of bringing my bud's boat back from a watery grave, he offered to lend a hand re-adjusting and tuning the engine...

The first thing he found was the trigger, under the flywheel, was not moving freely, so we pulled the flywheel and found that the original epoxy potting in the trigger had apparently received a pretty severe overheat and had literally boiled out the epoxy potting making for a very sticky and gooey mess...thus preventing any advance/retard of the timing...

We removed the unit from the engine and tested the resistance. It showed that everything was good to go, so my mission Saturday afternoon was to clean all the old goop off and re-pot the unit using some epoxy...

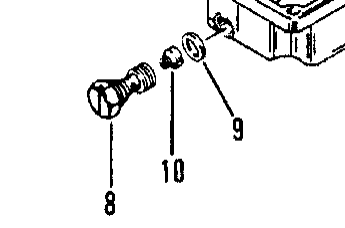

Here is a shot of the trigger after re-potting...

2-The next shot is us removing and remounting the flywheel using some shade tree ingenuity...

He had the correct puller, which we used to pull the flywheel...sorry, didn't get a pic of it...

And 3- He had noticed that besides the timing being way off, the carb linkage was also poorly adjusted...so he set the pick-up timing, and the full advance timing, along with adjusting the carb linkage...

After all was said and done, by Sunday afternoon, we had some fully charged batteries, had run a compression check on the motor, which indicated a solid foundation, and fired this puppy up...

After fiddling with some minor timing tweaks and getting the motor to run fairly well, he realized the top two carbs were not flowing properly...

The engine was basically running off of the bottom carb only...

That's when he told me to remove the jets and inspect them to make sure they were not clogged from sitting for so long...

Well, that's when Murphy showed up, uninvited as usual...

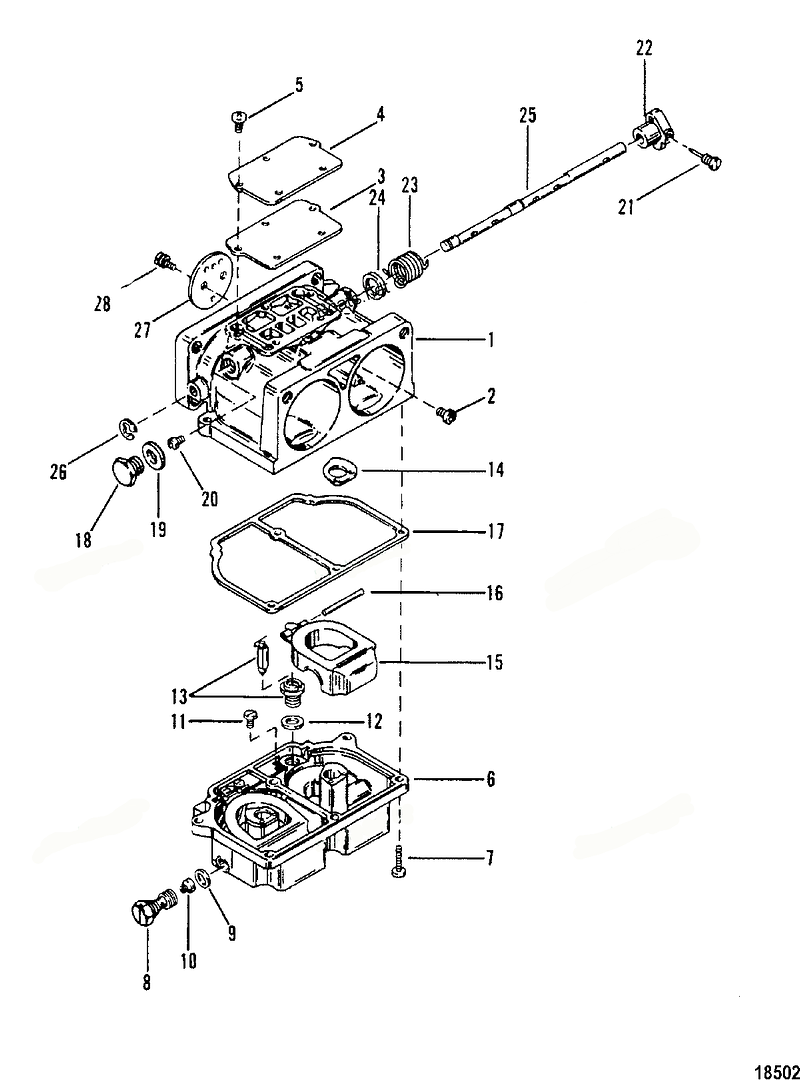

While removing the 4 main jets from the Top two carbs, the threaded portion was corroded and the jets broke off inside the carbs...

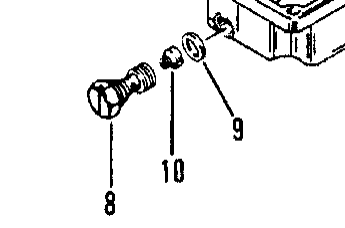

see #8 in the diagram...they broke at the point where they get narrow and are drilled crosswise...

Which basically brought everything to a screeching halt...

Anyhow, I am now in the process of spraying some penetrating oil into each of the orifices and will be trying to remove the broken jets during the next few days...

Our hope is that if they can be removed, new jets are still available, and after some cleaning, we will order them and replace...

The other option we are looking at is to find some matching carbs that are either in useable shape or rebuild-able, and go that route...

As soon as I know what direction we are headed, I'll be back to let you guys know...

Best to all and happy Prez Day!