Junkyardroad

Cadet

- Joined

- Aug 29, 2020

- Messages

- 12

I have followed many build threads and searched everywhere for answers to this question.

Background:

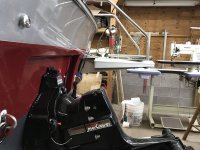

1989 Maxum 20' open bow - 5.0 Alpha 1 Gen 1 230 hp s/n 0449447

This boat was our family vacation for 15 years, and that sentimental value has overridden the expense of the resto-mod.

My Thunderbolt IV module failed by every diagnostic I can find. I have replaced it with a HEI with all new OEM internals, I cannot, will not, spend ~$500 for the Merc replacement. I have installed a 350.

The interruptor can kill the motor momentarily by grounding thru the tach sensor. My new shift cable is installed exactly as instructed, and the engine runs and shifts perfectly without the interruptor. (I haven't splashed the boat yet, this part is among the last steps.)

My switch is verified good, normally open. Cables are free and lubricated. The 'rocker' on the manfold for the shift cable is lubed.

It seems that if this mechanism is to ground the coil momentarily, the attachment for the shift cable must be moved by the shift cable casing being pulled briefly by the red cable attached to the shifter handle.

It seems this has to be done by friction, not by cable travel limit, or the switch would remain closed during operation? Thus grounding the coil and killing the engine.

Unless there was some magic in the TV 4 module, the switch remaining closed at full reverse would have prevented the engine from running? My switch 'rocker' never moves unless the boat is full reverse throttle. It cannot be dictated by throttle postition or it would not be momentary.

Seems like I have exhausted all the adjustment variables at this point.

Any advice appreciated.

Background:

1989 Maxum 20' open bow - 5.0 Alpha 1 Gen 1 230 hp s/n 0449447

This boat was our family vacation for 15 years, and that sentimental value has overridden the expense of the resto-mod.

My Thunderbolt IV module failed by every diagnostic I can find. I have replaced it with a HEI with all new OEM internals, I cannot, will not, spend ~$500 for the Merc replacement. I have installed a 350.

The interruptor can kill the motor momentarily by grounding thru the tach sensor. My new shift cable is installed exactly as instructed, and the engine runs and shifts perfectly without the interruptor. (I haven't splashed the boat yet, this part is among the last steps.)

My switch is verified good, normally open. Cables are free and lubricated. The 'rocker' on the manfold for the shift cable is lubed.

It seems that if this mechanism is to ground the coil momentarily, the attachment for the shift cable must be moved by the shift cable casing being pulled briefly by the red cable attached to the shifter handle.

It seems this has to be done by friction, not by cable travel limit, or the switch would remain closed during operation? Thus grounding the coil and killing the engine.

Unless there was some magic in the TV 4 module, the switch remaining closed at full reverse would have prevented the engine from running? My switch 'rocker' never moves unless the boat is full reverse throttle. It cannot be dictated by throttle postition or it would not be momentary.

Seems like I have exhausted all the adjustment variables at this point.

Any advice appreciated.

Last edited: