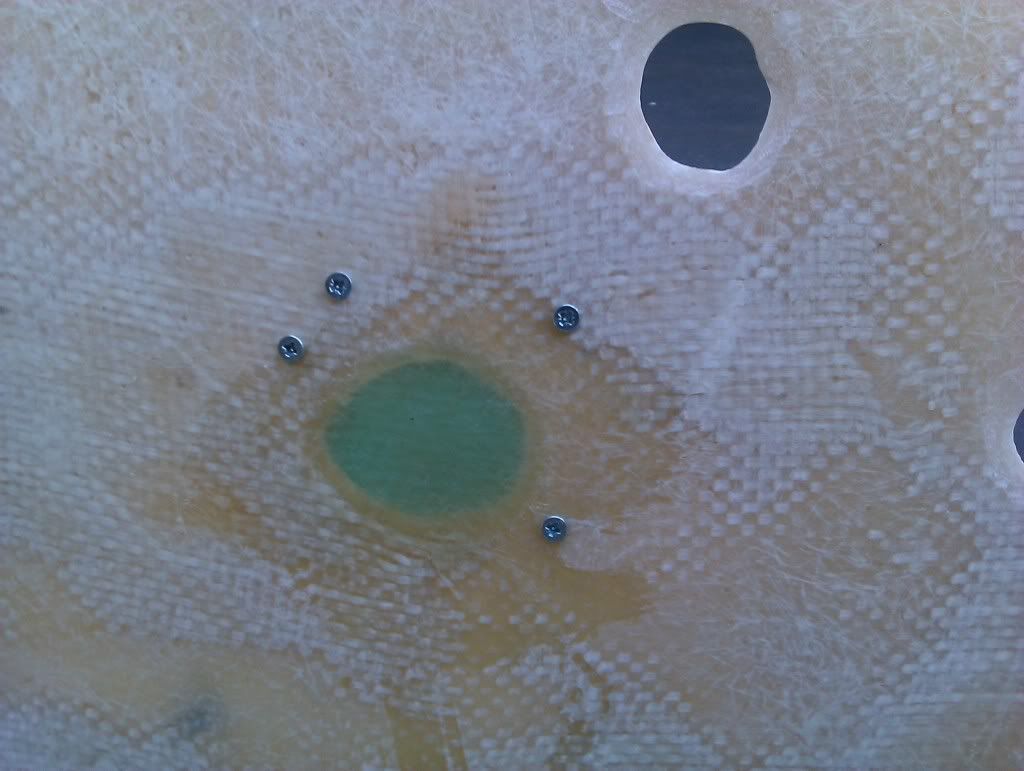

I decided after the last time I took my boat out that I needed a set of smart tabs, so naturally when I drilled the mounting holes in the transom a few weeks ago I found wet wood. Spent this afternoon stripping out the boat, I discovered in the process that the deck needs doing too, I'm hoping the stringers are ok but their probably not so I will be taking some core samples once the deck is off. I'll also be putting an under floor fuel tank and ice box if there's room.

I'm planning to fill the transom cut out most likely using formica backed with plyboard and 2x4's as the mold, cutting out the splash well and putting a pod/bracket with a swim platform. I'll be using polyester resin with 1808

I have no way of removing the cap and no where to put it even if I could remove it so I'll be cutting the cap just back from the transom, I'll be molding a new cap for the transom anyway so repair wont be a big deal.

A few pics of the boat before I started removing things.

Today's work.

I'm planning to fill the transom cut out most likely using formica backed with plyboard and 2x4's as the mold, cutting out the splash well and putting a pod/bracket with a swim platform. I'll be using polyester resin with 1808

I have no way of removing the cap and no where to put it even if I could remove it so I'll be cutting the cap just back from the transom, I'll be molding a new cap for the transom anyway so repair wont be a big deal.

A few pics of the boat before I started removing things.

Today's work.

Last edited: