Maybe you didn't scroll down far enuf on the page...

Transoms (updated 06/28/2016):

Epoxy

When using Epoxy for your transom it's basically the same as for Stringers. You'll use 17 oz Cloth instead of 1708 Biaxial and

NO CSM! You could also use a couple of layers of 8.5oz glass. With epoxy lighter weight glass and multiple layers is sometimes a better method to build bulk and strength. Everything else is basically the same. Always precoat your wood with a coat of resin then apply you first layer of cloth. Ensure all air bubbles are worked out Pay attention to the edges.

For aluminum boats the use of 17oz fabric is optional. Doesn?t really matter. 3-4 coats of epoxy followed by Paint will yield a transom that will last LONG time as long as you take care to ALWAYS predrill and then coat the holes and the Hardware with epoxy at the time of installation.

Polyester Resin

Note:

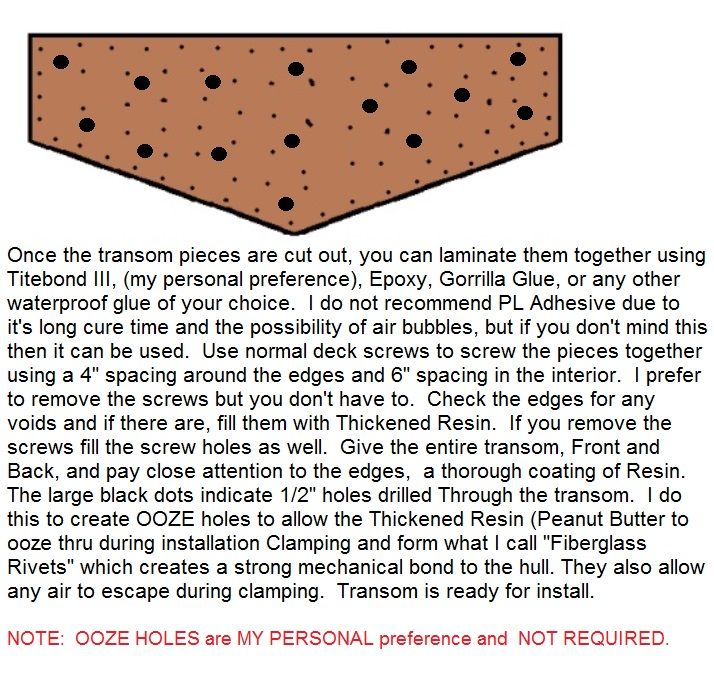

Note: When using screws as clamps, it's best to predrill the holes a bit oversiized on one piece of the transom. This keeps the piece from catching the screw threads and allows the other piece to be drawn up tight against the pre-drilled piece.

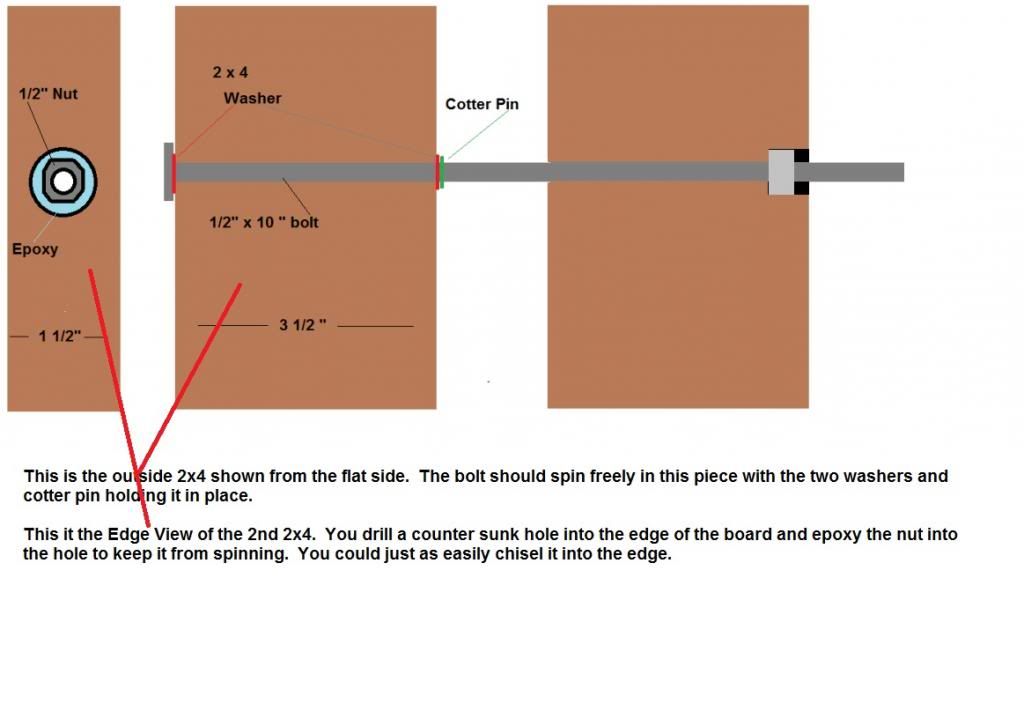

Pics of clamps I recommend for clamping an Outboard Style Transom when the top cap of the boat has been removed. I modified the construction of them just a bit using bolts instead of all thread. Takes a bit longer to build em but I like em better. Doing it this way I can use my 3/8" air drive ratchet to tighten em down which make is a lot faster to clamp em down. You need to be as fast as possible when you are using that much PB. Don't want it to set up on you before you get it clamped in place. Speed is of the essence!!!!

FINISHING UP THE TRANSOM INSTALL.

Once the transom is clamped into the boat, All that's left is to form the fillets and lay the glass. During clamp up, If you elected to create the OOZE holes you'll need to be prepared to smooth out the PB as it oozes out of the holes as well as form the fillets from the ooze out around the edges of the transom. You'll probably need to have a bit extra PB to form the fillets. A large Plastic Spoon is a great tool for forming these fillets and a bondo spreader is great for cleaning up the fillets and knocking down the inevitable left over waste and nubs that will occur. The cleaner and smoother you can make these fillets now the less work you'll have later when it all cures. After everything cures in a couple of hours you can remove the clamps and check for any rough spots on the fillets and sand them smooth. Cut your first layer of 1708 glass so it will extend out onto the sides and bottom of the hull approx 4-5 inches. I like to use Masking tape to hold it in place along the top edge of the transom and hull sides while I fit it in place and make my cuts. You can then start applying resin. Once the first layer starts to "Kick" and harden You can prepare to do the next layer and have it extend out onto the hull approx. 8-10". and repeat the resin process. If you want a smoother appearance you can follow up with a layer of 1.5 oz CSM to Hide the weave of the 1708 fabric. The Transom installation is now complete.