1985 Wellcraft Scarab I

350 crate motor replaced a merc 260. Has alpha one gen one out drive. I dont really have any serial numbers as they are all painted over or missing..

So I pulled my drive off at the end of the summer last year and lots of gear oil came out from the drive shaft bellows area. Looks like my upper was passing oil.... like a lot of it.

I just bought the boat and only had it on the lake for a couple of hours just to see if it ran or float etc. Seemed to do ok but I didnt go crazy with it since I didnt know much about the boat yet.

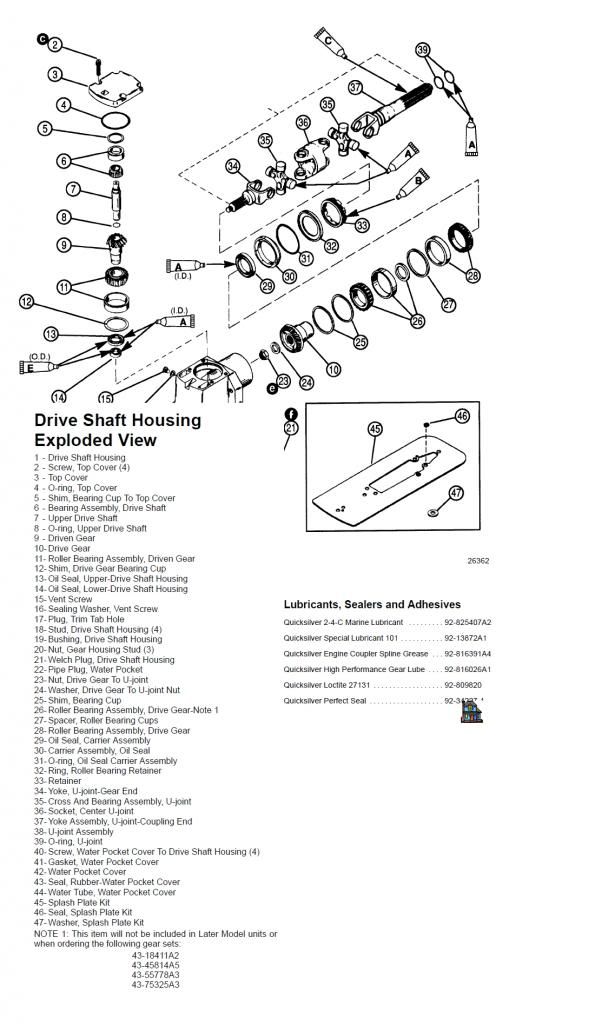

Anyway I suspect that the oil seal on the horizontal drive shaft is bad. I guess I assume thats what keeps the oil in the drive right? Is this something I can replace my self? It looks like I need a special tool to remove the drive shaft. And theres some shims I need to get everything back together right? Everything else looks like its in good shape. Everything I can see anyway like the u joint and drive shaft etc..

Should I just bring it to a shop and have them go through it? I havent read too many posts about people disassembling these units.

Thanks for any information!

350 crate motor replaced a merc 260. Has alpha one gen one out drive. I dont really have any serial numbers as they are all painted over or missing..

So I pulled my drive off at the end of the summer last year and lots of gear oil came out from the drive shaft bellows area. Looks like my upper was passing oil.... like a lot of it.

I just bought the boat and only had it on the lake for a couple of hours just to see if it ran or float etc. Seemed to do ok but I didnt go crazy with it since I didnt know much about the boat yet.

Anyway I suspect that the oil seal on the horizontal drive shaft is bad. I guess I assume thats what keeps the oil in the drive right? Is this something I can replace my self? It looks like I need a special tool to remove the drive shaft. And theres some shims I need to get everything back together right? Everything else looks like its in good shape. Everything I can see anyway like the u joint and drive shaft etc..

Should I just bring it to a shop and have them go through it? I havent read too many posts about people disassembling these units.

Thanks for any information!