Tafflad

Chief Petty Officer

- Joined

- Oct 23, 2007

- Messages

- 544

I have changed props many times, always set to correct torque, now have DuoProp.

Removing rear prop straight forward, and aware of tool required to remove front prop nut.

However the official VolvoPenta tool 3862797 appears to be a T-bar tool.

As they specify a torque, does the tool also take a square drive bit for a torque wrench.?

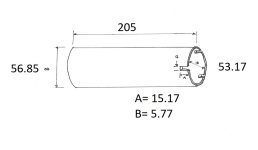

Anybody made one of these ? or know where I can get dimensions ?

Removing rear prop straight forward, and aware of tool required to remove front prop nut.

However the official VolvoPenta tool 3862797 appears to be a T-bar tool.

As they specify a torque, does the tool also take a square drive bit for a torque wrench.?

Anybody made one of these ? or know where I can get dimensions ?