Hi.

I had a 100 Merc on my boat where the leg was long and the keel line was half way through the prop,

I now have a 235 Johnson on it with and xl leg which i have another problem.

It works fine in the water but when i get a little speed up it starts spraying a large amount of water and slows me down.

I looked while a mate steered and it looks like the leg is too long now and it sits too lowwhere you can see the keel line, as this area is a large round part thats whats causing the spray.

My 2 questions are...

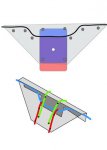

1, where should the keel of the boat be inline with A b c or D?

2, how would i get the motor high enough as from the keel line to letter a (the first cavitation plate) is 90mm and i only have 105mm from the bottom bolt hole to the edge of the transom?

Thanks for any advice or help.

I had a 100 Merc on my boat where the leg was long and the keel line was half way through the prop,

I now have a 235 Johnson on it with and xl leg which i have another problem.

It works fine in the water but when i get a little speed up it starts spraying a large amount of water and slows me down.

I looked while a mate steered and it looks like the leg is too long now and it sits too lowwhere you can see the keel line, as this area is a large round part thats whats causing the spray.

My 2 questions are...

1, where should the keel of the boat be inline with A b c or D?

2, how would i get the motor high enough as from the keel line to letter a (the first cavitation plate) is 90mm and i only have 105mm from the bottom bolt hole to the edge of the transom?

Thanks for any advice or help.