craigkenney

Cadet

- Joined

- Aug 14, 2021

- Messages

- 9

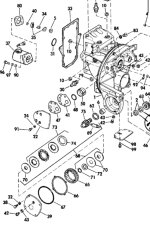

I have a 1980 seaswirl with an OMC stinger prop 3 solenoid lift up/down system. Since the last time I had it in the ocean and or lakes, have tried 3 lift motors thinking cheap might be just cheap but didn't solve the problem. The problem is the prop won't go up by itself without me lifting up the prop while hitting the up button. Electrically from switch to lift motor everything is good getting power and ground correctly, it does go down perfectly.

Parts replaced:

1. up solenoid

2. lift motor assembly--replaced to see if would help cause

3. tilt clutch assembly and seal kit--was replaced due to water in oil

Don't understand if there is anything else that i"m missing in the system that I'm overlooking. Not much found online about how the system operates other than the electrical portion.

Anyone know about these systems?

Parts replaced:

1. up solenoid

2. lift motor assembly--replaced to see if would help cause

3. tilt clutch assembly and seal kit--was replaced due to water in oil

Don't understand if there is anything else that i"m missing in the system that I'm overlooking. Not much found online about how the system operates other than the electrical portion.

Anyone know about these systems?