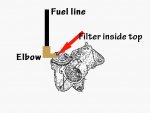

Once you get it back together and your leaking-gas issue has been addressed, if you're still lacking power I would suggest you take another look at the distributor belt. If it's one tooth off in the wrong direction (I want to say to the left, but I can't remember which side ), it'll pop and will fight you trying to get it timed and tuned.

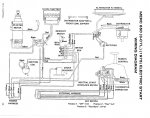

Also, it's very important that you use the proper instructions for aligning both the flywheel and the distributor. I have a service manual that shows a couple of different locations for the plastic timing indicator, but never showed the page shown here in this thread - which just happens to be the one for my motor. I sure could've used it when I was starting out! I checked your Serial number, and your S/N's batch is the same as mine (well, depending upon where you look it up. Another source shows your S/N - 3549507 - as a 1973-ish Merc). Mine's 4140802. In any case, if it looks like yours, the instructions Merc gave you should be correct for yours.

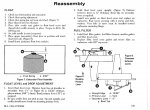

My plastic timing indicator just wasn't there, so I used the old tried and true method of popping the spark plugs and feeling the top of the #1 piston stroke using a small dowel stick. You're looking for that sweet-spot where it 'floats' at the top of the piston stroke. That's your TDC (Top Dead Center).

You can't be any more sure of TDC than that. At TDC, you'll see that the TDC mark on the flywheel is right at the spot where the timing indicator points to, or where the indicator was parked before it disappeared.. . .

This will let you know whether the flywheel was taken off and put back on using the wrong bolt holes. In any case, the #1 piston never lies! No matter what year you have, that's how you can find your TDC.

When mine is at TDC, my distributor belt-driven pulley has a little pointer sticking out from its side that (when it's set correctly) rests just over a little extension in the casting below it. Mine's on the left side of the casting, but still over the casting.

I just wanted to offer that up as a good place to start. Being sure of your TDC and your distributor position is like laying a good foundation. Everything else rests on it. I hope this helps.

I'm staying subscribed and following your progress, J.T.! Good luck, and let us know what you find.

JM