mr300z87

Senior Chief Petty Officer

- Joined

- Sep 15, 2010

- Messages

- 698

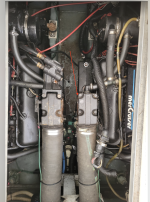

My wife and I are the new owners of a 1990 Sea Ray Sundancer 310 with a pair of 7.4L Bluewater inboards I do not have the serial #s but they are definitely 90 vintage Gen 4s. I know they need some exhaust work there is corrosion where the Manifold and elbow meet. I also know they are full closed cooled so the manifold have coolant in them only the elbow see raw/salty water and water jackets between them should be a block off. My question is what am in for? What usually needs replacing on these engines both elbows and manifolds or can I get lucky and only need gaskets and elbows? I know I wont know for sure until I tear it apart.

All my experience prior has been with raw cooled IOs I know that with them in salty water is all or engine failure. It's cold her in NJ this time a year except for the occasional Dec day at 65 like today, so nothing is going to happen with this for a while just trying see what I am up against this spring. The only good thing about having to replace the manifolds too, is getting to the raw pump for replacement will be easier. The 7.4L Bravo in my old 250 dancer was a dream to work on compared to this beast. I will get it figured out though.

As always any advice is great appreciated and have a great holiday season.

Mike

All my experience prior has been with raw cooled IOs I know that with them in salty water is all or engine failure. It's cold her in NJ this time a year except for the occasional Dec day at 65 like today, so nothing is going to happen with this for a while just trying see what I am up against this spring. The only good thing about having to replace the manifolds too, is getting to the raw pump for replacement will be easier. The 7.4L Bravo in my old 250 dancer was a dream to work on compared to this beast. I will get it figured out though.

As always any advice is great appreciated and have a great holiday season.

Mike