This is somewhat of a doozy. I decided to start a new thread since the old one had moved from discovery to handled.

However, this is more like a continuation because so much has been altered.

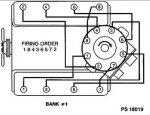

Background: 1995 5.7L. Fairly recent purchase. For 5 months used often, now on lift in florida. Discovered hydroLock situation. Tore motor down, replaced exhaust manifold/risers, pulled intake manifold and heads. Rebuilt Carter 4BBL, reassembled motor. Thunderbolt IV ignition. Set timing to 8 deg BTDC. cranked motor over w/o plugs to get oil distributed. put plugs in, motor fired and idled, albeit roughly and with a lot of valve tapping. let motor idle for 10 min. at min rpm. checked timing, still at 8btdc. so far, very happy.

After another 10 min of idling, port side still tapping with some very noisy ones. Method used to set valve lash: at compression stroke TDC, set 8 valves. turn rod by hand while tightenning rocker nut. when could not turn rod by fingers anymore, added 3/4 additional turn. then rotate crank 1 full rotation and set other 8 valves ( 4 intake, 4 exhaust) per clymer mercruiser shop manual.

thought i could quiet the tapping by adding 1/2 turn to all rocker nuts, so pulled valve cover and did just that.

and here is where I am stumped. afterwards, motor has never fired again.

Could that little adjustment on only the port side be causal to not running at all? I"m more inclined to believe something else is afoot.

motor cranks well, 2 new healthy batteries(on a tender), timing light on #1 wire shows pulse when cranking. carb jets are working. and yet, there is not even the remotest inkling of a firing. been at it all day.

Summary: has gas, has spark, good batts, was idling earlier, timing light shows triggering, (new plugs)...and dead to the world.

By The Way...: mechanical oil guage showed good oil pressure, and water flowing fine at idle check, also engine needed very little cranking to jump to life earlier.

I am stumped.

Out of daylight for today, will test port side compression tomorrow.

However, this is more like a continuation because so much has been altered.

Background: 1995 5.7L. Fairly recent purchase. For 5 months used often, now on lift in florida. Discovered hydroLock situation. Tore motor down, replaced exhaust manifold/risers, pulled intake manifold and heads. Rebuilt Carter 4BBL, reassembled motor. Thunderbolt IV ignition. Set timing to 8 deg BTDC. cranked motor over w/o plugs to get oil distributed. put plugs in, motor fired and idled, albeit roughly and with a lot of valve tapping. let motor idle for 10 min. at min rpm. checked timing, still at 8btdc. so far, very happy.

After another 10 min of idling, port side still tapping with some very noisy ones. Method used to set valve lash: at compression stroke TDC, set 8 valves. turn rod by hand while tightenning rocker nut. when could not turn rod by fingers anymore, added 3/4 additional turn. then rotate crank 1 full rotation and set other 8 valves ( 4 intake, 4 exhaust) per clymer mercruiser shop manual.

thought i could quiet the tapping by adding 1/2 turn to all rocker nuts, so pulled valve cover and did just that.

and here is where I am stumped. afterwards, motor has never fired again.

Could that little adjustment on only the port side be causal to not running at all? I"m more inclined to believe something else is afoot.

motor cranks well, 2 new healthy batteries(on a tender), timing light on #1 wire shows pulse when cranking. carb jets are working. and yet, there is not even the remotest inkling of a firing. been at it all day.

Summary: has gas, has spark, good batts, was idling earlier, timing light shows triggering, (new plugs)...and dead to the world.

By The Way...: mechanical oil guage showed good oil pressure, and water flowing fine at idle check, also engine needed very little cranking to jump to life earlier.

I am stumped.

Out of daylight for today, will test port side compression tomorrow.