CamaroMan

Petty Officer 1st Class

- Joined

- Mar 18, 2016

- Messages

- 330

Hi all.. trying to determine the timing setup on my 650 merc - currently tdc marks verified with dial gauge - its spot on. I put in new rings..

currently can only get it to idle at a few degrees ATDC, but from my understanding the motor shd idle retarded and make that chunky sound..

How do I reduce the advance without affecting the idle? I havent had it on a boat yet.. also - noticed grey drops (water/oil mixed?) coming from leg, I did put in a new exhaust plate gasket and seal it all up well.. not sure where thats coming from -

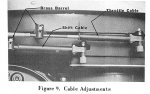

there are 3 screw on the front, one is for max advance (not concerned right now about that), another says idle (this seems to move the dizzy first from the cable slider), and another one says pickup. I noticed my pickup is touching the carbs even at idle, they seem to close though but ill have to double check - the pickup arm looks a little bent imo -

I have been following this gr8 write up -

currently can only get it to idle at a few degrees ATDC, but from my understanding the motor shd idle retarded and make that chunky sound..

How do I reduce the advance without affecting the idle? I havent had it on a boat yet.. also - noticed grey drops (water/oil mixed?) coming from leg, I did put in a new exhaust plate gasket and seal it all up well.. not sure where thats coming from -

there are 3 screw on the front, one is for max advance (not concerned right now about that), another says idle (this seems to move the dizzy first from the cable slider), and another one says pickup. I noticed my pickup is touching the carbs even at idle, they seem to close though but ill have to double check - the pickup arm looks a little bent imo -

I have been following this gr8 write up -