ScottinAZ

Master Chief Petty Officer

- Joined

- Jun 25, 2009

- Messages

- 865

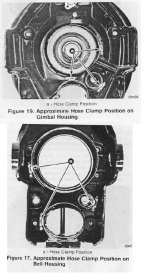

Ok, normally I would just put the clamps back in the approximate place they were, but that aint happening. Even using the flexible tool to get to the clamps, most of them were located in areas where there isnt even access for that.

Is there a preferred clocking on the clamps that while still difficult, isnt impossible. I ended up cutting the bellows to get the bellhousing off, and then fighting the clamps when I could see them.....

Is there a preferred clocking on the clamps that while still difficult, isnt impossible. I ended up cutting the bellows to get the bellhousing off, and then fighting the clamps when I could see them.....