Kranjack20

Petty Officer 2nd Class

- Joined

- May 7, 2023

- Messages

- 105

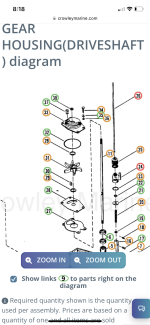

Hey guys. I got this impeller rebuild kit for my ‘88 Mariner 25hp and I got everything together impeller wise but in these pictures it looks like the seal isn’t making its way all the way down to the face plate? I took it apart and checked it multiple times. Nothing is preventing it from going down further so I don’t know if this is normal but it doesn’t seem like it. After putting everything together I am also left with 4 little rubber washers that I don’t see on the diagram so does anyone know what to do with those? The pics of the impeller cover is from each side. Circled in yellow u can see how the middle is sticking up and not really getting flush with the plate. The bolts are tight too. Sorry for all the questions I don’t know much about boat motors Im used to dirtbikes and quads. Thanks.