diggin4grouper

Seaman

- Joined

- Mar 25, 2012

- Messages

- 52

might be useful to some on here

pouring your own sinkers can be very cost effective if your like me and lose a bunch while fishing ( fishing holes with structure you will lose a bunch )

the way I'll do this is I will tell you what you have to do and then the picture of said items will follow

"warning"this is do at your own risk , please do it in an outside area and do not drop hot castings in a bucket of water as the will explode apart and cause injury to you and surrounding people and pets

here is a list of items you will need ..

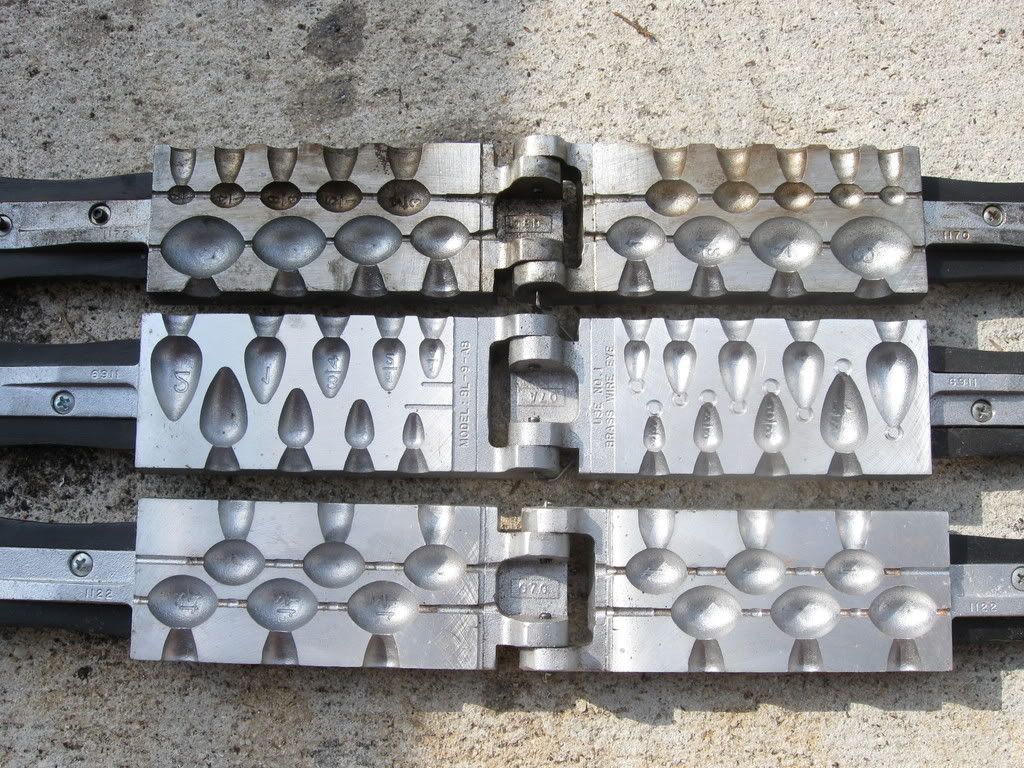

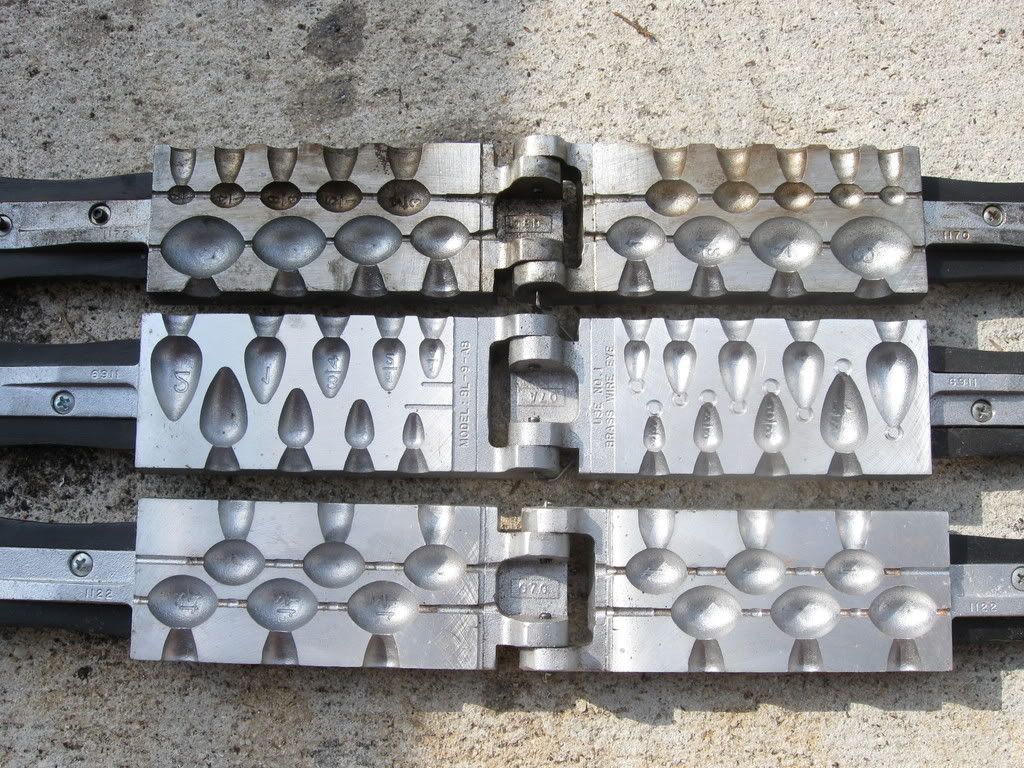

the molds of course , you can find them at many places http://www.do-itmolds.com/ and http://www.snlcorp.com/ are where I get mine , but use can find them at bass pro and other tackle suppliers.

a turkey fryier ,a cast iron skillet , cast iron ladel , and a good pair of leather gloves, this will be useful to melt down the lead and prep it for ingot casting

pouring your own sinkers can be very cost effective if your like me and lose a bunch while fishing ( fishing holes with structure you will lose a bunch )

the way I'll do this is I will tell you what you have to do and then the picture of said items will follow

"warning"this is do at your own risk , please do it in an outside area and do not drop hot castings in a bucket of water as the will explode apart and cause injury to you and surrounding people and pets

here is a list of items you will need ..

the molds of course , you can find them at many places http://www.do-itmolds.com/ and http://www.snlcorp.com/ are where I get mine , but use can find them at bass pro and other tackle suppliers.

a turkey fryier ,a cast iron skillet , cast iron ladel , and a good pair of leather gloves, this will be useful to melt down the lead and prep it for ingot casting