kramerpage

Chief Petty Officer

- Joined

- Jul 26, 2010

- Messages

- 447

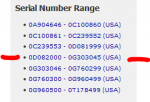

I looked at a boat today that had two different length motors on it. The original blew up from no oil. They replaced it with a shorter version. He said he would give me the original motor. So do you switch power heads and install old blown motor or switch lower units. I did not purchase boat because of this but I love it. Original counter rotation is on boat serial number below. I don't have serial for original standard rotation since it was on floor. Boat shows 117 hrs on motors. So I don't know to buy it or not. I would have marine mechanic do work. Any guess on money?

Attachments

Last edited: