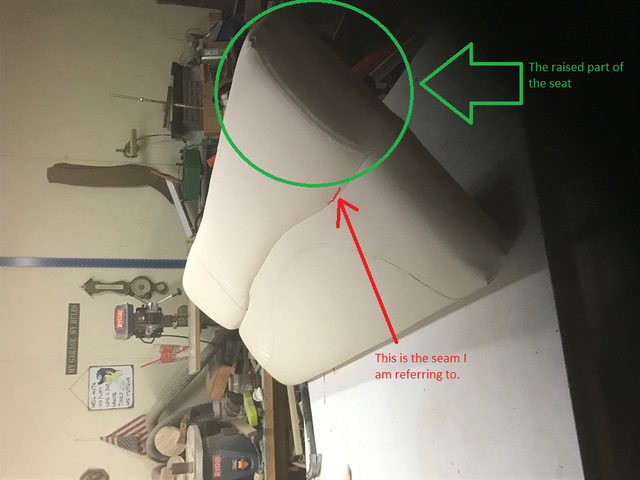

I am about to take on a new project replacing the carpet and seating in my boat. I'm going to be doing the upholstery myself and am looking for a sewing machine that will do the job.

I'm a bit lost on what type of sewing machine to look for.

What features do I need to look for in a sewing machine? I've heard that vintage sewing machines are good, but why? Also, the old singers seem to be popular but are the only sewing machines I should consider?

I found a couple sewing machines near by that I thought looked like they would be good, would these be good machines?

1. The first is a Vintage WHITE model 162 (listed for $75)

2. The second is a WHITE model 940 (Listed for $40)

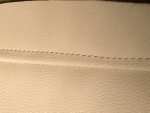

I am planning on mainly doing french seams like so:

Any advice would be great!

I'm a bit lost on what type of sewing machine to look for.

What features do I need to look for in a sewing machine? I've heard that vintage sewing machines are good, but why? Also, the old singers seem to be popular but are the only sewing machines I should consider?

I found a couple sewing machines near by that I thought looked like they would be good, would these be good machines?

1. The first is a Vintage WHITE model 162 (listed for $75)

2. The second is a WHITE model 940 (Listed for $40)

I am planning on mainly doing french seams like so:

Any advice would be great!