jasondainter

Seaman Apprentice

- Joined

- Jul 9, 2019

- Messages

- 39

Anyone know if this was a mistake on my part? I followed the manual religiously (against my judgement that these things felt too tight) and snap!

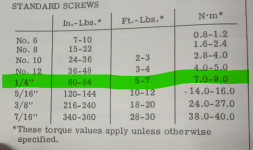

Yes I agree with F_R down below. When ever you deal with old outboards you are going to have a problem with bolts breaking. When that happens that is supper bad. (Removal) there is all kinds of tricks with penetrating oils and heat. Research and educate yourself on that. As far as your bolt, it looks like you tried to tighten that to what you thought was spec. You were wrong. Not being use to the metric system I'm not used to what you describe but I read your wrench and it said 30 to 50 ft pounds. More likely it's something in the inch pounds or it's metric equivalent. Most back yard mechanics, such as myself do lots by feel. One almost gets a sixth sense for it. I will admit that anything critical I will pull out the torque wrench. By the way, that's a stainless bolt. If you can't get a grip on it you will have to drill it out. It won't be fun.Anyone know if this was a mistake on my part? I followed the manual religiously (against my judgement that these things felt too tight) and snap!

I think you already had them out correct? If so, take one out and measure it. That particular bolt in America you could find just about anywhere. 1/4 20 (20 refers to the threads) and it's probably 1 1/2 to 2 inches. Not sure why the United States didn't convert to the metric system but I guess we are only partially perfect!Do you happen to know what length these are? Getting hold of these OEM is tough in Sweden but Ive sources imperial marine grade bolts locally that have a A4 Stainless Steel rating which I think would suffice?

Yea, I was thinking it might of said something in inch pounds cause it's a 1/4" bolt so not in foot pounds. But what I was thinking you said. I have never used a torque wrench on a water pump housing nor never thought too. Engine internals, yes, just used one last week tightening the nut on my Toyotas lower ball joint nut, but it's pinned and probably not necessary as long as it was tight as crap cause spec was 117#. But because of the scare of the nut backing off and almost falling apart on my wife from someone prior installation I used my half inch torque wrench on it.Yes I agree with F_R down below. When ever you deal with old outboards you are going to have a problem with bolts breaking. When that happens that is supper bad. (Removal) there is all kinds of tricks with penetrating oils and heat. Research and educate yourself on that. As far as your bolt, it looks like you tried to tighten that to what you thought was spec. You were wrong. Not being use to the metric system I'm not used to what you describe but I read your wrench and it said 30 to 50 ft pounds. More likely it's something in the inch pounds or it's metric equivalent. Most back yard mechanics, such as myself do lots by feel. One almost gets a sixth sense for it. I will admit that anything critical I will pull out the torque wrench. By the way, that's a stainless bolt. If you can't get a grip on it you will have to drill it out. It won't be fun.

As F_R says the bolts are 1/4" 20 ... thats 1/4" diameter and 20 threads per inch which is Unified fine or UNFThanks!!

The manual officially knows best and I officially need to go learn how to measure bolts

I believe you made an error here, the 1/4" x20 tpi is considered a course thread, the 28 tpi is the fine threadAs F_R says the bolts are 1/4" 20 ... thats 1/4" diameter and 20 threads per inch which is Unified fine or UNF

7/16" is the head or spanner jaw size measured "across flats" (AF)

View attachment 367329

You may find this website useful to bookmark. It relates standard head / spanner sizes to bolt diameter.

Spanner Jaw Sizes

Useful guide on spanner to nut/bolt relationships, and the selection and use of spanners and socket setswww.crawford-space.co.uk

You are not the first to have confused head size with bolt size. You'll find a similar thing with metric bolts and spanner sizes

Another tip is...when threading bolts into a blind hole, you should clean out any crud in that blind hole that could cause the bolt to bottom out and snap off. I always clean out the threaded hole and run a tap in there to be sure the threads are good. This little step can save lots of broken boltsThanks!!

The manual officially knows best and I officially need to go learn how to measure bolts

And like was true it was inch pounds.As F_R says the bolts are 1/4" 20 ... thats 1/4" diameter and 20 threads per inch which is Unified fine or UNF

7/16" is the head or spanner jaw size measured "across flats" (AF)

View attachment 367329

You may find this website useful to bookmark. It relates standard head / spanner sizes to bolt diameter.

Spanner Jaw Sizes

Useful guide on spanner to nut/bolt relationships, and the selection and use of spanners and socket setswww.crawford-space.co.uk

You are not the first to have confused head size with bolt size. You'll find a similar thing with metric bolts and spanner sizes