Hello! I have a 2010 Volvo Penta 5.0 GXi and have noticed a grinding noise when I'm turning left or right. This has gotten progressively worse over the past 6 months to the point where I no longer felt I should run it. I did some research and it looks like it may be the gimbal bearing, u-joints or both. So I took it to a mechanic and they came back with this quote. I'm not sure if this is reasonable as I have never taken this boat in for any significant repairs. Before I got the boat a year ago it was sitting on a lift for 4 years without any use. The engine has about 350 hours on it.

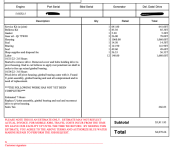

The mechanics quote is for replacing the gimbal bearing, pivot housing, u-joints and bellows, plus labor.

I want expecting to have to replace all of those parts, the cost of the pivot housing has me blown away and I'm just confused as to why I would need a new housing in the first place since the engine is not damaged. Could they not put the housing back on after replacing the gimbal bearing, u-joints and bellows?

All said & done they want $4,078 to fix it. Full quote attached.

I would love to get some opinions on this before I commit to this price. Thank you in advance!

- Miles

The mechanics quote is for replacing the gimbal bearing, pivot housing, u-joints and bellows, plus labor.

I want expecting to have to replace all of those parts, the cost of the pivot housing has me blown away and I'm just confused as to why I would need a new housing in the first place since the engine is not damaged. Could they not put the housing back on after replacing the gimbal bearing, u-joints and bellows?

All said & done they want $4,078 to fix it. Full quote attached.

I would love to get some opinions on this before I commit to this price. Thank you in advance!

- Miles

Attachments

Last edited: