Few days ago someone messaged me for measurements on my custom motor mount. I told him I'd post details on the main board in case anyone else was interested.

So I took a few pics to outline what's involved. First of all here are the overall measurements.

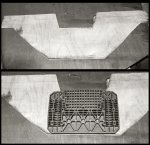

And this is how I usually start out. Once I've cut a base board to the right dimensions, I use the original Intex motor mount plate to mark out where all the holes for the u-bolts sit.

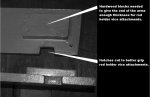

As regards the extension arms, it all depends on what kind of rod holders you go with. This was my solution for using Savage Gear holders.

I also drill holes at the ends of each extension arm so I can fit a bungee which attaches to rung on side of boat giving extra stability.

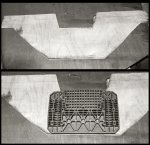

This next bit is probably the trickiest part.

Let me explain what's going on here. I originally built this unit using just half inch ply to try and keep the weight down, but found it was a little flimsy, especially if you bumped something with the extension arms. So I just cut another half inch thick template and doubled up the plate for strength. However 1 inch of ply means you can barely tighten the motor mount nuts, as most of the u-bolt threads are recessed inside the two sheets of ply. To get around this I cut holes in one sheet of the ply so that the nuts and u-bolts are really only coming through one sheet. This way you can loosen nuts to fold everything flat and never have to take them off again.

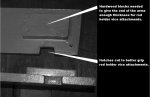

It's important to use quality hardwood for the strips where your extension arms will bolt on. I used decking, you can usually find lengths of the stuff in the bargain bin of your local hardware store.

I use plain white wood for the extension arms which is weaker. The idea being, if there's a catastrophic collision out on the water, the extension arm will rip off at the bolts, leaving the motor mount, engine and everything else intact. Better to lose a rod and reel than your engine, sonar etc.

And this is what it looked like on the water yesterday ready to set off.

Now please note the extension arms are actually angled outwards. If you don't angle them, your rod butts will be digging into both your thighs. In this position both rods are by your side and within easy reach should you hit a fish while trolling. The best way to figure out your angles is to build the back plate first, attach to your inflated boat, then place your extension arms on top and mark off your preferred angles.

Here's a view from inside the boat showing where the sonar sits.

Having the sonar position here with it's shaft pressed against the rear side of the boat eliminates the one major flaw these all- in-one sonar units have. When moving at any speed with a trolling motor, the Humminbird will begin to vibrate in it's holder and try to pop out. By positioning it here, between the motor mount and boat side, you can troll full speed with no issues.

View of a rod holder from my chair.

Shot showing where the bungee cord goes.

This motor mount is a work in progress, this design being the latest in a line of seven, I'm constantly tweaking.

Two issues. One the strength of the attachable extension arms. Right now I'm using two bolts for each arm, I may upgrade to a triangular arrangement of THREE if they start to move around too much. However, I recently caught a 22lb northern pike while trolling this way and there were no issues.

Second possible issue is the bottom nut of the rod holder rubbing against the boat. In the above pic you can see it's touching the boat. I've tried raising the height of the motor mount base board a few inches, but depending on condition this contact can still occur. The solution is to place a small towel there, or glue on a reinforcing patch.

A final thought. This custom motor mount is designed for my needs using specific fishing gear.

I troll for big pike and use baitrunner reels which I've been told are not used much in the States. Is this true? These are often used for carp or pike fishing from the bank in conjunction with alarms. Here's a pic.

I've been using them for trolling as I find their second free running gear can be tightened so that the trolling lure no longer pulls the line off. When a fish strikes it's not as hard on the custom motor mount extension arms, but more importantly, if your lure catches an underwater tree, the free runner will give out line.

I once snagged up at speed and realised I'd forgotten to engage the freerunner. Fortunately the custom motor mount and it's extension arm held firm, but the boat did turn sharply though.(I use braid of 30lbs up)

I can't think of anything else. If anyone has questions feel free to ask.