skunkedskippy

Petty Officer 2nd Class

- Joined

- Apr 30, 2017

- Messages

- 130

I just finished rebuilding my stringers and transom. Reinstalled my bell housing and inner transom plate. Looking for advice on getting the location for the front mount brackets. They are "L", or angle brackets, if it matters.

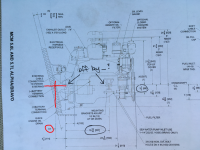

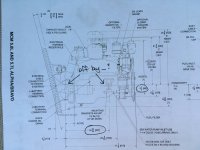

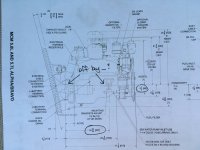

According to a diagram I found, the distance from rear-to-front mounts is 19-15/16" and the distance from the crankshaft centerline to bottom of front mounts is 3-1/2". I circled these numbers in the image below.

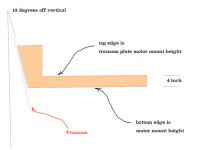

The crankshaft centerline also appears to be very close to the top of the rear mount surface, and bottom of the front bracket (that bolts to the engine), but not perfectly lined up.

So the centerline doesn't seem to be perfectly inline with the top of the rear mount, or bottom of the front mount (arrows drawn above). Should I figure this into my measurements? If so, how much is it off by?

To get the rear-to-front location, I laid a straight edge along the rear mount holes, drew a line on the stringers and measured 19-15/16" forward from there.

To get the the front mount bracket (or bottom of motor mount) height I laid the straight edge on top of the rear mount and measured 3-1/2" down. As mentioned above, if the centerline and mount are off by X", do I need to measure somewhere around 3-3/4" instead? Or is the difference small enough that the front mounts can be adjusted to make up for it?

Also, once I get the front mount height (marked towards the REAR, as I'm doing), what is an easy way mark it at the actual front location, where it will be bolted?

Once I get the locations dialed in, the plan is to bolt the front motor mounts and brackets to the engine, lower it down and thread the rear mount bolts, mark the front holes, lift it back out to drill the holes, and then back down for final installation. Now that I think about it, if I do it like this I might not even need to measure the rear-to-front distance.

Please let me know if there is a better/easier way to do any of this. I'm a newb if you can't tell.

According to a diagram I found, the distance from rear-to-front mounts is 19-15/16" and the distance from the crankshaft centerline to bottom of front mounts is 3-1/2". I circled these numbers in the image below.

The crankshaft centerline also appears to be very close to the top of the rear mount surface, and bottom of the front bracket (that bolts to the engine), but not perfectly lined up.

So the centerline doesn't seem to be perfectly inline with the top of the rear mount, or bottom of the front mount (arrows drawn above). Should I figure this into my measurements? If so, how much is it off by?

To get the rear-to-front location, I laid a straight edge along the rear mount holes, drew a line on the stringers and measured 19-15/16" forward from there.

To get the the front mount bracket (or bottom of motor mount) height I laid the straight edge on top of the rear mount and measured 3-1/2" down. As mentioned above, if the centerline and mount are off by X", do I need to measure somewhere around 3-3/4" instead? Or is the difference small enough that the front mounts can be adjusted to make up for it?

Also, once I get the front mount height (marked towards the REAR, as I'm doing), what is an easy way mark it at the actual front location, where it will be bolted?

Once I get the locations dialed in, the plan is to bolt the front motor mounts and brackets to the engine, lower it down and thread the rear mount bolts, mark the front holes, lift it back out to drill the holes, and then back down for final installation. Now that I think about it, if I do it like this I might not even need to measure the rear-to-front distance.

Please let me know if there is a better/easier way to do any of this. I'm a newb if you can't tell.