83mulligan

Senior Chief Petty Officer

- Joined

- Feb 7, 2009

- Messages

- 687

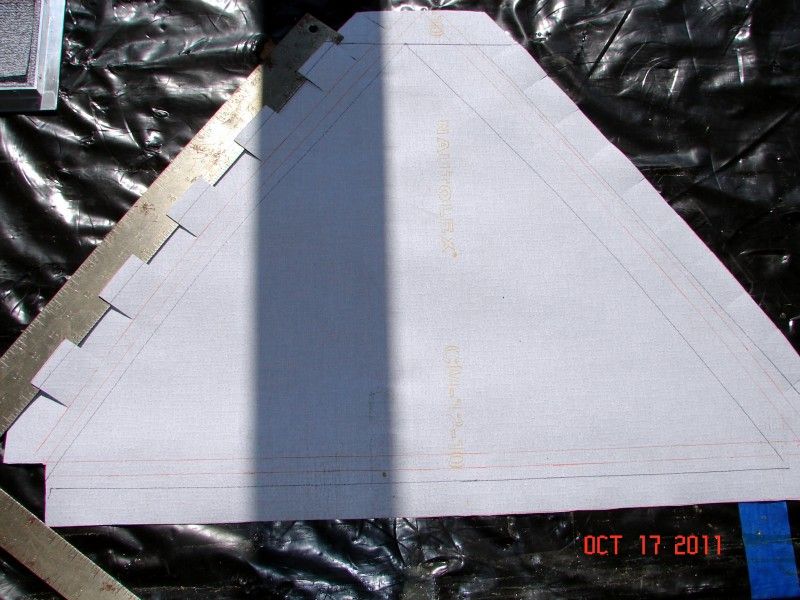

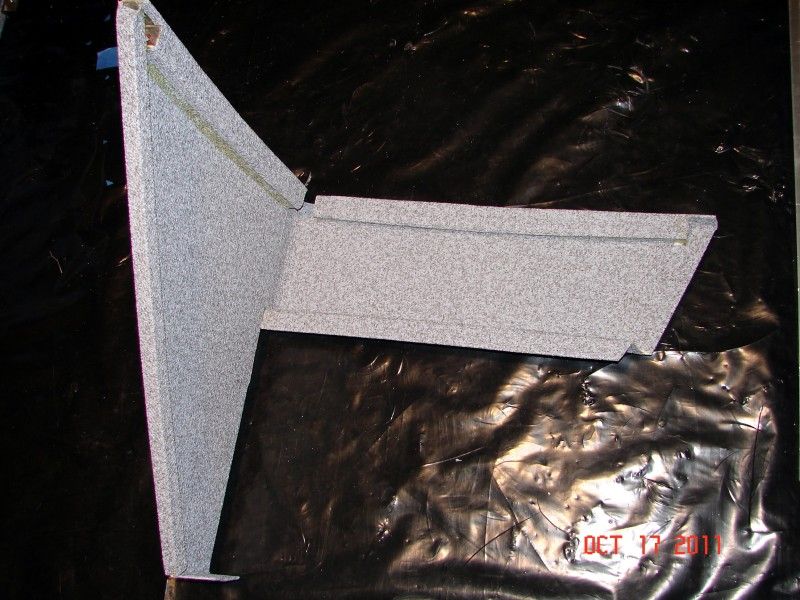

Below is a shot of two deck boards I want to glass together. I want to do this so that my vinyl is a seamless sheet covering entire floor. There will be a 2" wide rib under the seam, so I just want to glass the bottom side and pb the top so it is smooth. The only strength it needs strength for is so that I can vinyl cover the deck out of the boat and carry it into the boat and rivet it down. Once it sits in the boat the seam is fully supported underneath by the rib. So, how much glass do I need on the underneath side to hold it together.