Rivergator

Petty Officer 1st Class

- Joined

- May 7, 2013

- Messages

- 240

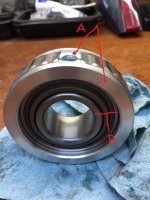

The gimbal bearing in my Alpha One Gen1 housing right now happens to be the sealed (non-greasable) type. The bearing itself feels good, solid and tight but it feels that it is lacking grease. You can tell by turning it by hand that it just doesn't have that draggy feeling of a well greased bearing. Since there is nothing I can do about it and I know that by next summer this bearing could go belly up on me I already ordered a new bearing and seal to have it ready when and should it happen and this time I made sure that I got the greasable type, the one that has the grease hole in it and needs to be lined up with the housing so it can be greased from the outside through the nipple. Today I got this bug up my butt and decided to look into it a little deeper to see how this all works and also to make sure that the bearing is properly packed by installing a grease nipple on the hole in the outer aluminum ring and pump some grease into it to see if it actually comes out somewhere. In my opinion some should definitely come out somewhere between the upper and lower race of the actual bearing that sits in the aluminum ring, but nothing came out anywhere. The pressure I exerted on my grease gun was quite severe and grease should have escaped somewhere for sure but the only place where some grease came out was where the nipple was screwed into the outer ring. Also I remembered a neat little demo Chris did where he put a gimbal bearing in a vice and then moved the bearing around in the outer alumunum ring. I tried that and no way did that work for me and I pushed hard to the point were the whole vice wanted to move but not the bearing, no way. That gimbal bearing is not swiveling. Coming back to the grease part. Has anybody ever taken one of these apart and actually has seen a grease hole going through the outer race of the actual bearing so that grease actually gets to the balls or is this all a scam and no grease ever gets to the bearing even though the bearing is sold as "greasable" just because it has a grease hole in the outer ring. Let's face it once the bearing is installed nobody knows what goes on with the bearing until if fails. We assume that we always lub'd the bearing when putting a grease gun on the housing nipple, but did we really. Suspicious minds need answers. At least the brand new bearing that I have on my bench acts like no grease is going into the actual bearing. On picture #1 A is the outside alu ring with the grease whole and B is the actual bearing. Picture #2 shows my temporary grease nipple. Picture #3 shows the actual bearing which I assume should be able to move inside the alu ring and can anybody tell me what the purpose for the 2 cut outs C is? Thanks