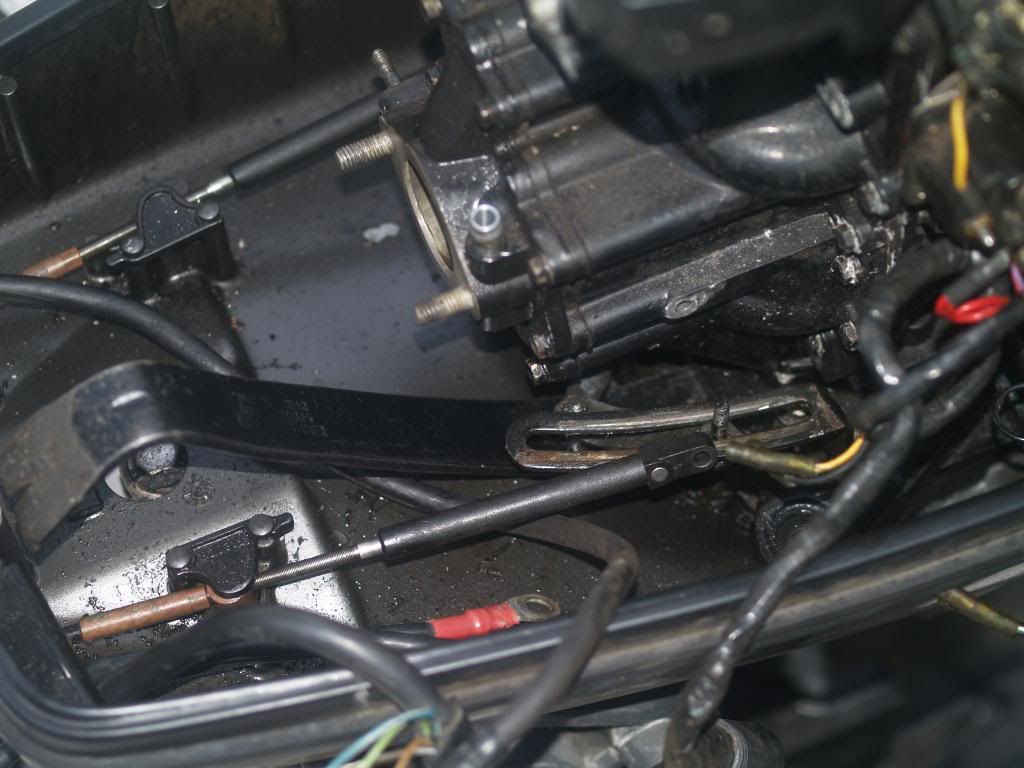

Re: Force 120 with low compression seeking advice

Yes I was surprised to see it there. It feels like hard plastic. I am thinking maybe it is from the upper cowl. The upper cowl has some areas that look like have been repaired. Maybe a piece came off and was sucked in?

Wonder what the heck that's from??

Rubber? Plastic?

Yes I was surprised to see it there. It feels like hard plastic. I am thinking maybe it is from the upper cowl. The upper cowl has some areas that look like have been repaired. Maybe a piece came off and was sucked in?