This is a continuation of another thread - testing solenoid and where to get replacement that I started due to starting problems. At first I thought the problem was a starting system issue. After checking starter, solenoid, battery, cables, etc I checked compression as was recommended by other forum members. And I found cylinder one to only have around 110 while 2, 3, 4 were between 149 and 151. I am starting a new thread here as suggested because my problem does not see to be related to starting system.

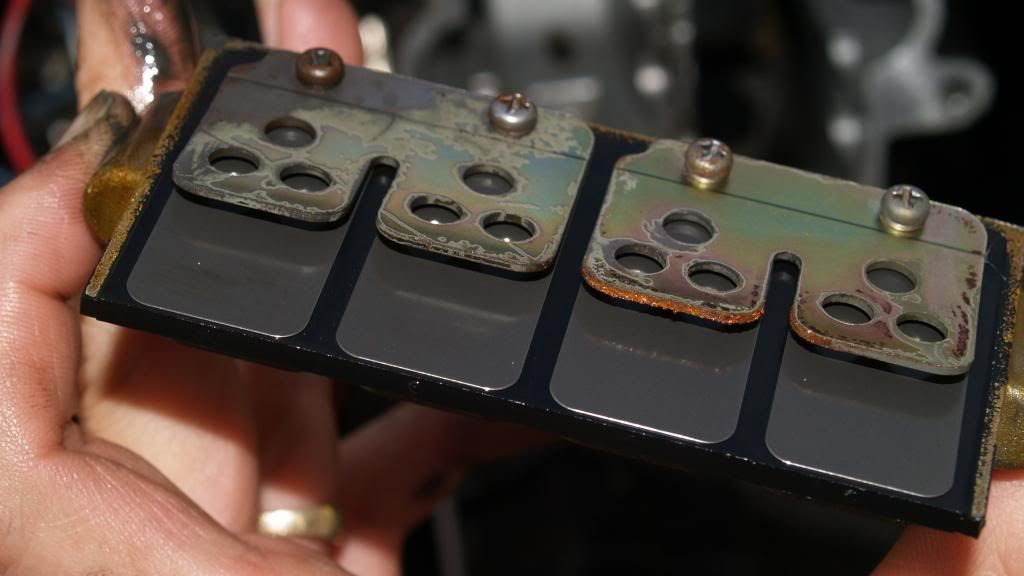

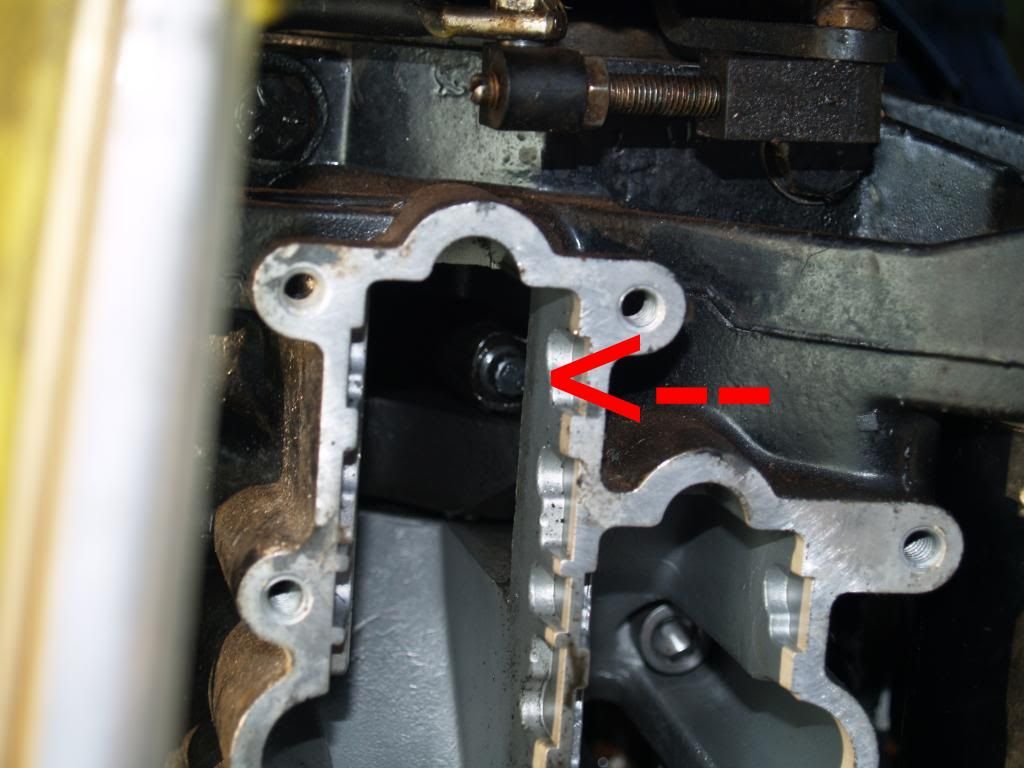

As recommended by forum I have removed the head. The following is video of the pistons with head removed. It was hard to get good pics of all the cylinder walls so I tried here to get a more complete view with video. I do not really see any physical damage myself, and the scuffs on the cylinder walls are not too bad and not any worse in the cylinder with low compression than the others. However, I do see a lot more hard, black buildup on the top of piston one than any of the others. One member has recommended that I go in from the intake and try to remove piston one to inspect. Or, it could be I have bad Reed valves. I am considering doing that next and looking closely at the reeds to see if that is my problem. Please let me know any thoughts on the condition or recommended next steps. Thanks in advance.

As recommended by forum I have removed the head. The following is video of the pistons with head removed. It was hard to get good pics of all the cylinder walls so I tried here to get a more complete view with video. I do not really see any physical damage myself, and the scuffs on the cylinder walls are not too bad and not any worse in the cylinder with low compression than the others. However, I do see a lot more hard, black buildup on the top of piston one than any of the others. One member has recommended that I go in from the intake and try to remove piston one to inspect. Or, it could be I have bad Reed valves. I am considering doing that next and looking closely at the reeds to see if that is my problem. Please let me know any thoughts on the condition or recommended next steps. Thanks in advance.